Product Overview

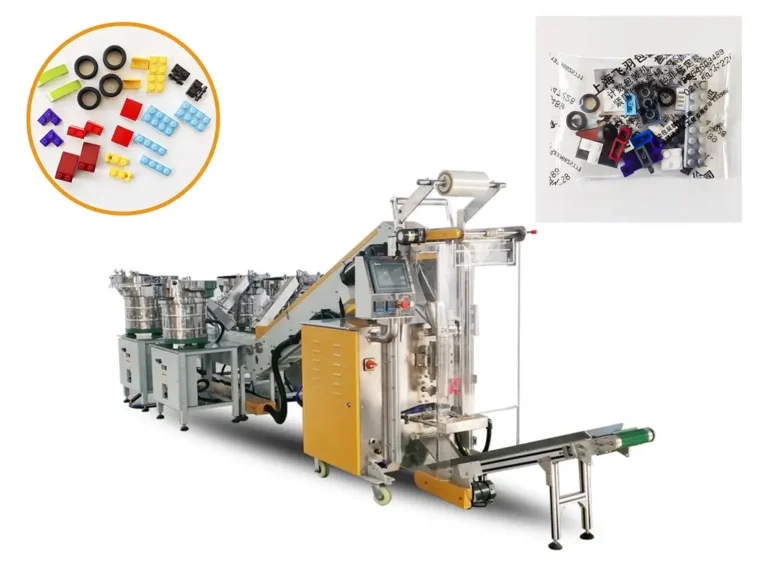

The Lego Brick Toy Counting Packing Machine (Model: FY-420C) is specifically designed for counting and packaging building blocks. Using advanced sensing technology and an automated control system, it can quickly and accurately count each building block and package it into specified quantities. This machine improves production efficiency, reduces labor costs, and ensures consistent packaging quality.

Key Features & Advantages

- Automatic counting and packaging: Precisely counts 1–20 pieces per bag and supports up to 30 types per bag.

- High-speed operation: Packing speed ranges from 10–60 bags per minute depending on product and configuration.

- Flexible bag sizes: Handles bags from L 50–300 mm and W 50–200 mm.

- Mixed or single-type packaging: Suitable for single-specification or multiple types per bag.

- Versatile packaging materials: Compatible with PP/CPP, PA/PE, PET/PE, and PE films.

- Easy operation: PLC control system with user-friendly interface.

- Durable and reliable: Industrial-grade design ensures stable, long-term operation.

Applicable Industries & Scenarios

- Industries: Toy manufacturers, building block suppliers, educational product distributors.

- Scenarios:

- Counting and packaging Lego or other building blocks for retail and wholesale.

- Preparing mixed-specification kits of building blocks for assembly sets.

- High-speed production lines requiring precise count and consistent packaging.

Technical Specifications

| Model | FY-420C |

| Packing Speed | 10–60 bags/min |

| Packing Material | PP/CPP, PA/PE, PET/PE, PE |

| Packing Size | L 50–300mm; W 50–200mm |

| Packing Type | Mixed/Single/Compartment |

| Counting Capacity | 1–20 pcs/bag; 1–30 kinds/bag |

| Power | AC220V–380V / 50–60Hz / 2KW |

Workflow

Feeding Lego bricks → Vibratory bowl feeding → Counting → Chain bucket conveyor → Bag forming → Product loading → Sealing → Printing/labeling (optional) → Finished bag output

Customization & Expansion Options

- Additional vibratory bowls for higher throughput and multi-type feeding.

- Optional printing and labeling for batch codes, barcodes, or set information.

- Integration with checkweigher for quality control.

- Custom bag sizes and materials to match building block dimensions.

- Conveyor system for automated collection of finished bags.

Application Cases

- Toy Manufacturer: Automated counting and packaging of building blocks for retail kits.

- Educational Product Supplier: Mixed or single-type packs prepared for classroom sets.

- Wholesale Distributor: High-speed packaging for large-volume building block orders.

After-Sales Service

- Installation & commissioning: On-site or remote support.

- Warranty: 12-month standard warranty with spare parts supply.

- Technical support: 24/7 online or phone assistance.

- Operator training: Provided with operation and maintenance manuals.

- Spare parts supply: Fast delivery for common wear parts.

FAQ

- Q: Can this machine package multiple types of Lego bricks in one bag?

A: Yes, it supports up to 30 types per bag. - Q: What is the maximum counting capacity per bag?

A: 1–20 pcs per type. - Q: Which bag materials are supported?

A: PP/CPP, PA/PE, PET/PE, and PE films. - Q: What is the typical packing speed?

A: 10–60 bags per minute depending on product size and configuration.