Productos

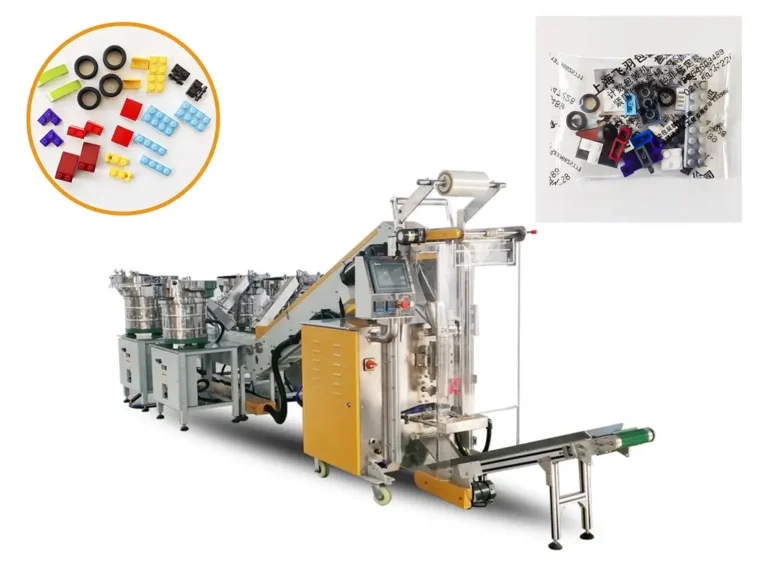

La máquina contadora y empaquetadora de juguetes Lego Brick (modelo: FY-420C) está diseñada específicamente para contar y empaquetar bloques de construcción. Utilizando tecnología de detección avanzada y un sistema de control automatizado, puede contar de forma rápida y precisa cada bloque de construcción y empaquetarlo en cantidades especificadas. Esta máquina mejora la eficiencia de la producción, reduce los costes de mano de obra y garantiza una calidad de embalaje uniforme.

Principales características y ventajas

- Recuento y envasado automáticos: Cuenta con precisión de 1 a 20 piezas por bolsa y admite hasta 30 tipos por bolsa.

- Funcionamiento a alta velocidad: La velocidad de envasado oscila entre 10 y 60 bolsas por minuto en función del producto y la configuración.

- Tamaños de bolsa flexibles: Admite bolsas de 50-300 mm de largo y 50-200 mm de ancho.

- Envasado mixto o de un solo tipo: Adecuado para una sola especificación o múltiples tipos por bolsa.

- Materiales de envasado versátiles: Compatible con películas PP/CPP, PA/PE, PET/PE y PE.

- Fácil manejo: Sistema de control PLC con interfaz fácil de usar.

- Duradera y fiable: El diseño de calidad industrial garantiza un funcionamiento estable a largo plazo.

Industrias y escenarios aplicables

- Industrias: Fabricantes de juguetes, proveedores de bloques de construcción, distribuidores de productos educativos.

- Escenarios:

- Contar y empaquetar Lego u otros bloques de construcción para la venta al por menor y al por mayor.

- Preparación de kits de especificaciones mixtas de bloques de construcción para juegos de montaje.

- Líneas de producción de alta velocidad que requieren un recuento preciso y un envasado homogéneo.

Especificaciones técnicas

| Modelo | FY-420C |

| Velocidad de embalaje | 10-60 bolsas/min |

| Material de embalaje | PP/CPP, PA/PE, PET/PE, PE |

| Tamaño del embalaje | L 50-300 mm; A 50-200 mm |

| Tipo de embalaje | Mixto/Simple/Compartimentado |

| Capacidad de recuento | 1-20 unidades/bolsa; 1-30 tipos/bolsa |

| Potencia | AC220V-380V / 50-60Hz / 2KW |

Flujo de trabajo

Alimentación de ladrillos Lego → Alimentación vibratoria de cuencos → Recuento → Transportador de cangilones de cadena → Formación de bolsas → Carga de productos → Sellado → Impresión/etiquetado (opcional) → Salida de bolsas terminadas.

Opciones de personalización y ampliación

- Cubetas vibratorias adicionales para un mayor rendimiento y alimentación de varios tipos.

- Impresión y etiquetado opcionales para códigos de lote, códigos de barras o información de ajuste.

- Integración con controladora de peso para el control de calidad.

- Tamaños y materiales de bolsa personalizados para adaptarse a las dimensiones de los bloques de construcción.

- Sistema transportador para la recogida automática de bolsas acabadas.

Casos de aplicación

- Fabricante de juguetes: Recuento y embalaje automatizados de bloques de construcción para kits de venta al por menor.

- Proveedor de productos educativos: Paquetes mixtos o de un solo tipo preparados para conjuntos de aula.

- Distribuidor mayorista: Embalaje de alta velocidad para pedidos de bloques de construcción de gran volumen.

Servicio posventa

- Instalación y puesta en marcha: Asistencia in situ o a distancia.

- Garantía: 12 meses de garantía estándar con suministro de piezas de repuesto.

- Asistencia técnica: Asistencia en línea o telefónica 24 horas al día, 7 días a la semana.

- Formación del operador: Provisto de manuales de funcionamiento y mantenimiento.

- Suministro de piezas de repuesto: Entrega rápida de piezas de desgaste comunes.

PREGUNTAS FRECUENTES

- P: ¿Puede esta máquina empaquetar varios tipos de ladrillos Lego en una misma bolsa?

R: Sí, admite hasta 30 tipos por bolsa. - P: ¿Cuál es la capacidad máxima de recuento por bolsa?

R: 1-20 unidades por tipo. - P: ¿Qué materiales de bolsas se admiten?

A: PP/CPP, PA/PE, PET/PE y láminas de PE. - P: ¿Cuál es la velocidad típica de envasado?

R: De 10 a 60 bolsas por minuto, según el tamaño y la configuración del producto.