Обзор продукции

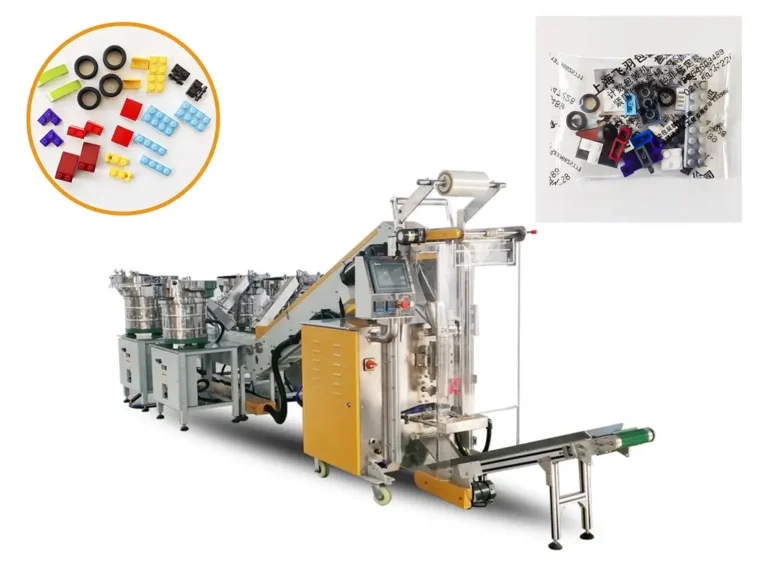

Машина для подсчета и упаковки игрушек Lego Brick (модель: FY-420C) специально разработана для подсчета и упаковки строительных блоков. Используя передовую сенсорную технологию и автоматизированную систему управления, она может быстро и точно пересчитать каждый строительный блок и упаковать его в заданное количество. Эта машина повышает эффективность производства, снижает трудозатраты и обеспечивает стабильное качество упаковки.

Ключевые особенности и преимущества

- Автоматический подсчет и упаковка: Точный подсчет 1-20 штук на пакет и поддержка до 30 типов на пакет.

- Высокоскоростная работа: Скорость упаковки составляет от 10-60 пакетов в минуту в зависимости от продукта и конфигурации.

- Гибкие размеры пакетов: Работает с пакетами длиной 50-300 мм и шириной 50-200 мм.

- Смешанная или однотипная упаковка: Подходит для упаковки одного вида или нескольких видов в один пакет.

- Универсальные упаковочные материалы: Совместим с пленками PP/CPP, PA/PE, PET/PE и PE.

- Простота эксплуатации: Система управления PLC с удобным интерфейсом.

- Прочность и надежность: Конструкция промышленного класса обеспечивает стабильную и длительную работу.

Применимые отрасли и сценарии

- Промышленность: Производители игрушек, поставщики строительных блоков, дистрибьюторы образовательных товаров.

- Сценарии:

- Подсчет и упаковка Lego или других строительных блоков для розничной и оптовой продажи.

- Подготовка наборов строительных блоков смешанной спецификации для сборочных комплектов.

- Высокоскоростные производственные линии, требующие точного подсчета и последовательной упаковки.

Технические характеристики

| Модель | FY-420C |

| Скорость упаковки | 10-60 мешков/мин |

| Материал упаковки | PP/CPP, PA/PE, PET/PE, PE |

| Размер упаковки | L 50-300 мм; W 50-200 мм |

| Тип упаковки | Смешанные/одиночные/квартирные |

| Счетная емкость | 1-20 шт/мешок; 1-30 видов/мешок |

| Мощность | AC220V-380V / 50-60Hz / 2KW |

Рабочий процесс

Подача кирпичиков Lego → Вибрационная подача в чашу → Счетчик → Цепной ковшовый конвейер → Формирование пакетов → Загрузка продукта → Запечатывание → Печать/маркировка (опция) → Выход готовых пакетов

Возможности настройки и расширения

- Дополнительные виброчаши для повышения производительности и многотипной подачи.

- Опциональная печать и маркировка для кодов партии, штрих-кодов или информации о наборе.

- Интеграция с контрольными весами для контроля качества.

- Нестандартные размеры и материалы мешков соответствуют размерам строительных блоков.

- Конвейерная система для автоматизированного сбора готовых пакетов.

Случаи применения

- Производитель игрушек: Автоматизированный подсчет и упаковка строительных блоков для розничных наборов.

- Поставщик образовательной продукции: Смешанные или однотипные упаковки, подготовленные для наборов в классе.

- Оптовый дистрибьютор: Высокоскоростная упаковка для крупносерийных заказов строительных блоков.

Послепродажное обслуживание

- Установка и ввод в эксплуатацию: Поддержка на месте или удаленно.

- Гарантия: 12 месяцев стандартной гарантии с поставкой запасных частей.

- Техническая поддержка: Круглосуточная помощь в режиме онлайн или по телефону.

- Обучение операторов: Предоставляются руководства по эксплуатации и техническому обслуживанию.

- Поставка запасных частей: Быстрая поставка быстроизнашивающихся деталей.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

- Вопрос: Может ли эта машина упаковать несколько видов кирпичей Lego в один пакет?

О: Да, он поддерживает до 30 типов на сумку. - В: Какова максимальная вместимость одного мешка?

A: 1-20 шт. на каждый тип. - В: Какие материалы для сумок поддерживаются?

A: Пленки PP/CPP, PA/PE, PET/PE и PE. - В: Какова типичная скорость упаковки?

A: 10-60 мешков в минуту в зависимости от размера и конфигурации продукта.