Screw Hardware Fastener Box Packaging Solution

Date: June 6, 2024 Categories: Solutions Views: 11,750

This packaging solution is designed for single-variety and high-volume products such as screws and hardware fasteners, and aims to achieve efficient and accurate box packaging through counting and weighing technology. The solution covers the entire process from counting, weighing to box packaging, ensuring that the number of products in each box is accurate and the weight is consistent.

- High-precision counting: Fiber optic counting device is used to ensure the accurate number of screws or fasteners in each package.

- Accurate weighing: Combined with weighing detection device, multiple re-inspections are performed to ensure that the weight of each package meets the standard.

- Efficient packaging: Integrated automated packing system reduces manual operations and improves packaging efficiency.

- Intelligent control: Equipped with intelligent control system, real-time monitoring of counting and weighing process to ensure packaging quality.

Detail:

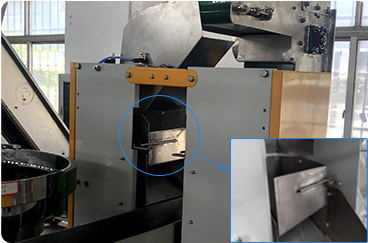

Fiber Optic Counting Device:

Function: Use fiber optic sensors to accurately count each screw or fastener.

Features: Overcome the limitations of traditional counting methods, with an accuracy rate of up to 100%.

Weighing and testing device:

Function: Use high-precision electronic scales to detect the weight of each batch of products.

Features: Multiple re-inspections ensure the consistency of the weight of each package.

Automatic box packing system:

Function: Automatically pack the counted and weighed products into boxes.

Features: Reduce manual intervention and improve packaging speed and accuracy.

Intelligent control system:

Function: Real-time monitoring of the entire packaging process, automatic adjustment of counting and weighing parameters.

Features: Easy to operate and maintain.

Workflow

- Product loading: Pour screws or fasteners into the loading hopper and send them to the counting device through the conveyor belt.

- Accurate counting: The products pass through the optical fiber counting device, count and record in real time.

- Weighing and detection: The counted products enter the weighing device to detect the weight of each batch of products.

- Qualified sorting: According to the weighing results, the products that meet the weight standards are sent to the packing area, and the unqualified products are returned for recounting.

- Automatic packing: Qualified products are automatically packed into the packaging box to complete the packaging.

- Packaging completion: Each packaging box undergoes the final inspection to ensure that the quantity and weight are correct before entering the warehousing or shipping link.

Advantages and benefits

- Accuracy: Through advanced counting and weighing technology, ensure that the quantity and weight of the products in each packaging box are fully in line with the standards.

- High efficiency: Automated equipment greatly increases packaging speed and reduces labor costs.

- Reliability: The intelligent control system monitors in real time to ensure the stability and reliability of the packaging process.

- Flexibility: Applicable to screws and fasteners of various specifications, easy to adjust and switch.

Customer support and service

- Technical consultation: Provide professional technical consulting services to help customers choose the most suitable equipment and solutions.

- Customized design: Design and manufacture dedicated non-standard equipment according to customer needs.

- Installation and commissioning: Provide equipment installation and commissioning services to ensure the normal operation of the equipment.

- After-sales service: Provide comprehensive after-sales service, including equipment maintenance, technical support and spare parts supply.

This packaging solution provides reliable packaging for single-variety and high-volume products such as screws and hardware fasteners through high-precision counting and weighing technology and efficient automated packing systems. We are committed to improving packaging efficiency, reducing costs, and ensuring product quality for our customers. Please contact us for more details.