Product Overview

The Hardware Packing Machine employs advanced counting technology to automatically count, bag, seal, print, and label hardware parts.

Designed for hardware kit , Furniture components, it boosts packaging efficiency while reducing labor costs for manufacturers and distributors.

Key Features & Advantages

Accurate Multi-Mode Counting: Supports single-item, mixed, and compartment packing.

High Productivity: 10–60 bags/min depending on configuration.

Flexible Packaging Types: Single, mixed, or compartmented kits.

Wide Material Compatibility: Works with PP, PA, PE, CPP, PET films.

Multi-SKU Capability: Up to 30 kinds per bag for mixed kits.

Integrated Printing & Labeling: Optional batch, date, barcode, QR code.

User-Friendly Operation: PLC touchscreen interface for easy recipe switching.

Robust Design: Industrial-grade frame for long-term stable operation.

Applicable Industries & Scenarios

Industries: Hardware manufacturing, fastener suppliers, furniture parts, electronics assembly, OEM kit production.

Use Cases:

- Packing assembly kits containing multiple small parts (compartment or mixed).

- High-speed single-item packing for screws, nuts, washers.

- E-commerce and retail small-part packaging where mixed assortments are required.

Typical Applications

- Mixed-Assortment Kits: 3–12 SKUs per kit for retail or e-commerce.

- Single-Part Fast Packing: Screws, nuts, washers packed at high speed.

- Compartment/Tray Kits: Electronics assembly or furniture kits with separate sections for each part.

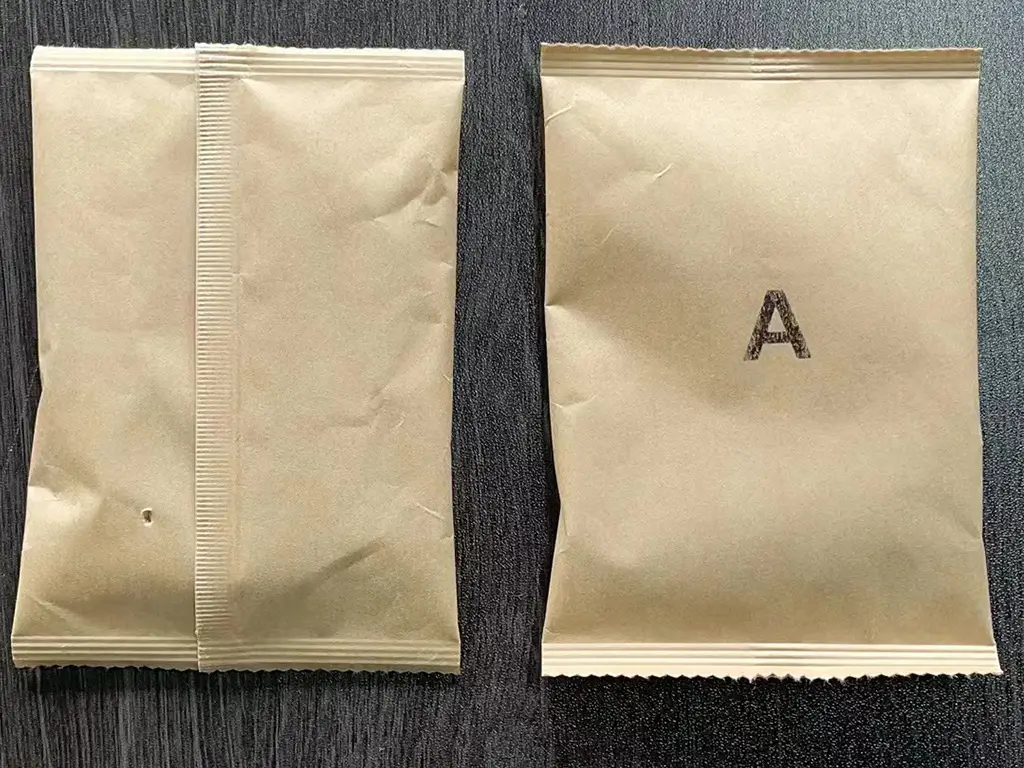

Hardware Packing Machine Samples

Technical Specifications

| Model | FY-240C | FY-420C |

| Packing size | L: 30-180mm, W: 50-140mm | L: 50-300mm, W: 50-200mm |

| Max film width | 300mm | 420mm |

| Packing material | PA/PE, PP/CPP, PET/PE | PA/PE, PP/CPP, PET/PE |

| Counting capacity | 1-20pcs/bag; 1-40 kinds/bag | 1-20pcs/bag; 1-40 kinds/bag |

| Packing speed | 10-60 bag/min | 10-60 bag/min |

| Power | AC220V/50-60Hz/2kW | AC220V/50-60Hz/2kW |

| Machine size | L*W*H: (n/2*600+2200mm)* 1500* 1650mm, n=the Qty of vibration bowl | L*W*H: (n/2*600+2200mm)* 1500* 1650mm, n=the Qty of vibration bowl |

Workflow

Feed parts → Vibratory feeder / bowl feeder → High-speed counting (single or multi-channel) → (Make-up counting if required) → Bag/tray forming or box positioning → Product loading into bag/compartment → Sealing / heat-seal → Printing/labeling → Finished product output

Customization & Expansion Options

- Multiple vibratory bowls or feeders to support higher feeding throughput or additional SKUs.

- Compartment/tray inserter for partitioned kits.

- Additional lanes/modules for simultaneous multi-SKU counting and merging.

- Print & label modules (batch, date, barcode, QR code).

- Reject or inspection station (metal detector / vision check) and weighing/checkweigher integration.

- Conveyor and cartoning/boxing interface for full-line automation.

- Custom recipes and MES/ERP connectivity.

Application Cases

- Fastener Manufacturer: Produced mixed-assortment kits (3–12 SKUs per kit) for retail, improving packing speed and reducing manual sorting.

- Furniture Parts Supplier: Single-spec packing for assembly bags at 40 bags/min during peak shifts.

- Electronics Assembler: Compartmented tray packing for small components, ensuring kit completeness and traceability.

After-Sales Service

- Installation & Commissioning: Remote startup assistance or engineer on-site commissioning.

- Warranty: 12-month standard warranty; extended warranty options available.

- Spare Parts: Common wear parts stocked for fast shipment.

- Training & Documentation: Operator training and maintenance manuals provided.

- Support: Technical support via phone/email, 24/7 service

FAQ

Q: Can Hardware Packing Machine pack multiple different parts into the same bag?

A: Yes — the FY-420C supports mixed packing and can handle multiple SKUs per bag (up to 30 kinds per bag depending on configuration). For mixed kits, we recommend configuring multiple feeders and verifying part compatibility.

Q: What does “compartment” packing mean?

A: Compartment packing means placing parts into partitioned trays or boxes (each compartment holds a specific part). The machine can load into preformed compartments or work with an inserter module.

Q: What is the maximum pieces per bag?

A: Standard counting per SKU is 1–20 pcs/bag. For multi-quantity single-SKU runs, capacities depend on part size and bag size (consult us for high-count configurations).

Q: Which film materials are supported?

A: PP, PA, PE, CPP, and PET films are supported; actual sealing parameters depend on the film type and thickness.