Product Overview

The Automatic Hardware Screw Bagging Machine (Model: FY-420C) is designed for efficient and accurate counting, weighing, and packaging of screws, nuts, bolts, and other hardware accessories. It supports single-type or mixed-type packaging, helping manufacturers save labor, improve accuracy, and ensure professional packaging quality.

Key Features & Advantages

- Automatic counting & packaging: Handles 1–20 pcs per bag, supports up to 30 types per bag.

- Flexible packaging types: Suitable for single, mixed, or compartment packaging.

- High-speed performance: Capable of 10–60 bags per minute depending on configuration.

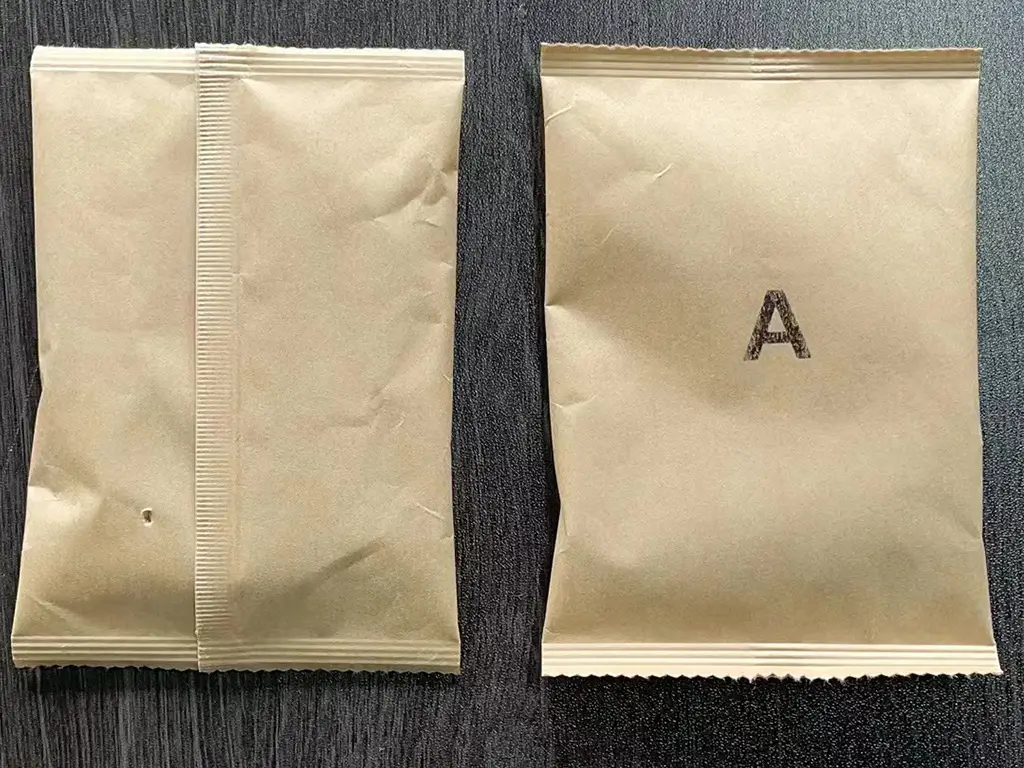

- Wide material compatibility: Works with PP/PA/PE/CPP/PET films.

- Adjustable bag size: L 50–300mm, W 50–200mm.

- User-friendly operation: Equipped with PLC control system for stability and ease of use.

- Durable & reliable: Industrial-grade machine with stable long-term operation.

Applicable Industries & Scenarios

Industries: Hardware manufacturing, furniture fittings, construction materials, logistics.

Scenarios:

- Packaging screws, bolts, and nuts for furniture kits.

- Preparing mixed hardware bags for distribution.

- High-speed packaging for hardware production lines.

Technical Specifications

| Model | FY-420C |

| Packing Speed | 10–60 bags/min |

| Packing Material | PP/PA/PE/CPP/PET |

| Packing Size | L: 50–300mm, W: 50–200mm |

| Packing Type | Mixed / Single / Compartment |

| Counting Capacity | 1–20 pcs/bag; 1–30 kinds/bag |

Workflow

Feeding hardware parts → Vibratory bowl feeding → Counting → Bag forming → Product loading → Sealing → Printing/labeling (optional) → Finished bag output

Customization & Expansion Options

- Multiple vibratory bowls for feeding different types of hardware.

- Optional labeling or printing for batch codes and traceability.

- Custom bag dimensions to match product requirements.

- Integration with checkweigher for quality assurance.

- Conveyor system for automatic collection of finished bags.

Application Cases

- Furniture Manufacturer: Packaging screws and fittings for DIY furniture kits.

- Hardware Supplier: Mixed hardware sets packaged for retail distribution.

- Logistics Center: Automated packaging to improve order fulfillment efficiency.

After-Sales Service

- Installation & commissioning: On-site or remote support available.

- Warranty: Standard 12-month warranty with spare parts supply.

- Technical support: 24/7 online or phone assistance.

- Training: Operator manuals and training provided.

- Spare parts supply: Fast delivery of common wear parts.

FAQ

Q: Can this machine handle mixed hardware packaging?

A: Yes, it supports single-type, mixed-type, and compartment packaging.

Q: What is the maximum number of types per bag?

A: Up to 30 different hardware types can be packed per bag.

Q: What is the typical speed?

A: The machine runs at 10–60 bags per minute depending on product and settings.

Q: Which bag materials are supported?

A: Compatible with PP, PA, PE, CPP, and PET films.