Wielofunkcyjna maszyna pakująca do liczenia sprzętu

Maszyna pakująca do liczenia sprzętu (model: FY-420C) wykorzystuje zaawansowaną technologię liczenia do automatycznego liczenia, pakowania, uszczelniania, drukowania i etykietowania części sprzętu. Zaprojektowana do szybkiego i dokładnego pakowania małych części, znacznie poprawia wydajność pakowania i zmniejsza koszty pracy dla producentów i dystrybutorów.

Wideo

Kluczowe cechy i zalety

Dokładne zliczanie w wielu trybach: Szybki system liczenia obsługuje liczenie pojedynczych sztuk, pakowanie mieszanych ilości i pakowanie przedziałowe.

Wysoka produktywność: Prędkość pakowania od 10 do 60 worków na minutę w zależności od produktu i konfiguracji.

Rodzaje opakowań elastycznych: Obsługuje opakowania pojedyncze, mieszane i przedziałowe (tacki/pudełka dzielone).

Szeroka kompatybilność materiałowa: Działa z foliami PP, PA, PE, CPP, PET i typowymi małymi torebkami plastikowymi/papierowymi.

Zdolność do obsługi wielu jednostek: Obsługuje do 30 różnych rodzajów w jednym worku (na konfigurację), idealny do zestawów i asortymentów.

Zintegrowane drukowanie i etykietowanie: Opcjonalne moduły drukowania/etykietowania numerów partii, dat i kodów kreskowych w celu zapewnienia identyfikowalności.

Obsługa przyjazna dla użytkownika: Sterowanie PLC z ekranem dotykowym do szybkiego przełączania receptur i przechowywania parametrów.

Solidna konstrukcja: Konstrukcja klasy przemysłowej zapewniająca stabilną i długotrwałą pracę oraz łatwą konserwację.

Odpowiednie branże i scenariusze

Branże: Produkcja sprzętu, dostawcy elementów złącznych, części mebli, montaż elektroniki, produkcja zestawów OEM.

Przypadki użycia:

- Pakowanie zestawów montażowych zawierających wiele małych części (przedziałowych lub mieszanych).

- Szybkie pakowanie pojedynczych elementów: śrub, nakrętek, podkładek.

- E-commerce i detaliczne opakowania na małe części, gdzie wymagane są mieszane asortymenty.

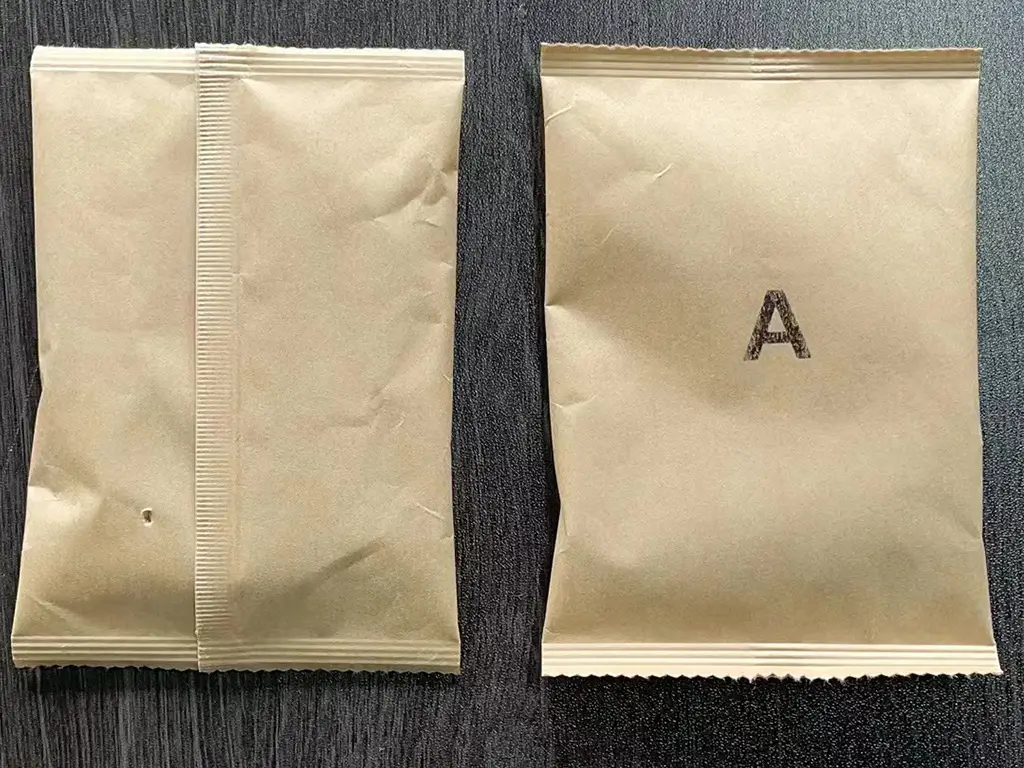

Próbki

Specyfikacja techniczna

| Model | FY-240C | FY-420C |

| Rozmiar opakowania | dł.: 30-180 mm, szer.: 50-140 mm | L: 50-300 mm, W: 50-200 mm |

| Maksymalna szerokość folii | 300 mm | 420 mm |

| Materiał opakowania | PA/PE, PP/CPP, PET/PE | PA/PE, PP/CPP, PET/PE |

| Zdolność liczenia | 1-20 sztuk/worek; 1-40 rodzajów/worek | 1-20 sztuk/worek; 1-40 rodzajów/worek |

| Prędkość pakowania | 10-60 worków/min | 10-60 worków/min |

| Moc | AC220V/50-60Hz/2kW | AC220V/50-60Hz/2kW |

| Rozmiar maszyny | L * W * H: (n / 2 * 600 + 2200 mm) * 1500 * 1650 mm, n = ilość bębna wibracyjnego | L * W * H: (n / 2 * 600 + 2200 mm) * 1500 * 1650 mm, n = ilość bębna wibracyjnego |

Uwagi: Rzeczywista prędkość i wydajność zależą od rozmiaru i kształtu części oraz wybranej konfiguracji podawania/liczenia.

Przepływ pracy

Podawanie części → Podajnik wibracyjny / podajnik miskowy → Liczenie z dużą prędkością (jedno- lub wielokanałowe) → (liczenie uzupełniające w razie potrzeby) → Formowanie worka / tacki lub pozycjonowanie pudełka → Ładowanie produktu do worka / komory → Uszczelnianie / zgrzewanie → Drukowanie / etykietowanie → Wyjście gotowego produktu

Opcje dostosowywania i rozbudowy

- Wiele bębnów wibracyjnych lub podajników do obsługi większej przepustowości podawania lub dodatkowych SKU.

- Wstawiacz przedziałów/tac do zestawów dzielonych.

- Dodatkowe pasy/moduły do jednoczesnego liczenia i łączenia wielu jednostek SKU.

- Moduły drukowania i etykietowania (partia, data, kod kreskowy, kod QR).

- Stacja odrzucająca lub kontrolna (wykrywacz metali / kontrola wzrokowa) oraz integracja z wagą kontrolną.

- Przenośnik i interfejs kartonowania/pakowania dla pełnej automatyzacji linii.

- Niestandardowe receptury i łączność MES/ERP.

Przypadki zastosowań

- Producent elementów złącznych: Produkcja zestawów mieszanego asortymentu (3-12 SKU na zestaw) dla handlu detalicznego, poprawa szybkości pakowania i ograniczenie ręcznego sortowania.

- Dostawca części do mebli: Pakowanie pojedynczych worków montażowych z prędkością 40 worków/min podczas szczytowych zmian.

- Monter elektronik: Podział na tacki do pakowania małych komponentów, zapewniający kompletność i identyfikowalność zestawu.

Obsługa posprzedażna

- Instalacja i uruchomienie: Zdalna pomoc przy uruchomieniu lub uruchomienie na miejscu przez inżyniera.

- Gwarancja: 12-miesięczna gwarancja standardowa; dostępne opcje rozszerzonej gwarancji.

- Części zamienne: Typowe części zużywalne dostępne w magazynie do szybkiej wysyłki.

- Szkolenia i dokumentacja: Dostarczone podręczniki szkoleniowe i konserwacyjne dla operatora.

- Wsparcie: Wsparcie techniczne i rozwiązywanie problemów przez telefon/email; priorytet wysyłki części zamiennych dla umów serwisowych.

FAQ

P: Czy ta maszyna może pakować wiele różnych części do tego samego worka?

O: Tak - FY-420C obsługuje pakowanie mieszane i może obsługiwać wiele jednostek SKU na worek (do 30 rodzajów na worek w zależności od konfiguracji). W przypadku zestawów mieszanych zalecamy skonfigurowanie wielu podajników i sprawdzenie zgodności części.

P: Co oznacza pakowanie "przedziałowe"?

O: Pakowanie przedziałowe oznacza umieszczanie części w podzielonych tacach lub pudełkach (każdy przedział zawiera określoną część). Maszyna może ładować do wstępnie uformowanych przegródek lub współpracować z modułem insertera.

P: Jaka jest maksymalna ilość sztuk w worku?

O: Standardowa liczba na jednostkę SKU wynosi 1-20 sztuk/worek. W przypadku serii wieloseryjnych z jednym SKU wydajność zależy od rozmiaru części i rozmiaru worka (skonsultuj się z nami w sprawie konfiguracji o dużej liczbie).

P: Jakie materiały filmowe są obsługiwane?

O: Obsługiwane są folie PP, PA, PE, CPP i PET; rzeczywiste parametry zgrzewania zależą od rodzaju i grubości folii.