Обзор продукции

Многотипная упаковочная машина для смешанной упаковки аппаратуры (модель: FY-520) предназначена для выполнения различных типов сложных задач по упаковке аппаратуры. Она заменяет большой объем ручной работы по подсчету и упаковке, значительно сокращая человеческие ошибки и трудозатраты. Благодаря передовой системе управления PLC, гибким возможностям подачи и цепному ковшовому конвейеру она идеально подходит для производителей, которым требуется смешанная или многотипная упаковка фурнитуры в больших объемах.

Ключевые особенности и преимущества

- Упаковка смешанного типа: Возможность упаковки нескольких видов фурнитуры в один пакет с высокой точностью.

- Эффективная работа: Скорость упаковки 10-60 пакетов/мин, в зависимости от продукта и конфигурации.

- Точный подсчет: Поддерживает 5-40 штук в одном пакете, обеспечивая точную подготовку наборов.

- Цепной ковшовый конвейер: Прочный конвейер с жесткими пластиковыми ящиками обеспечивает стабильную передачу материала после подсчета.

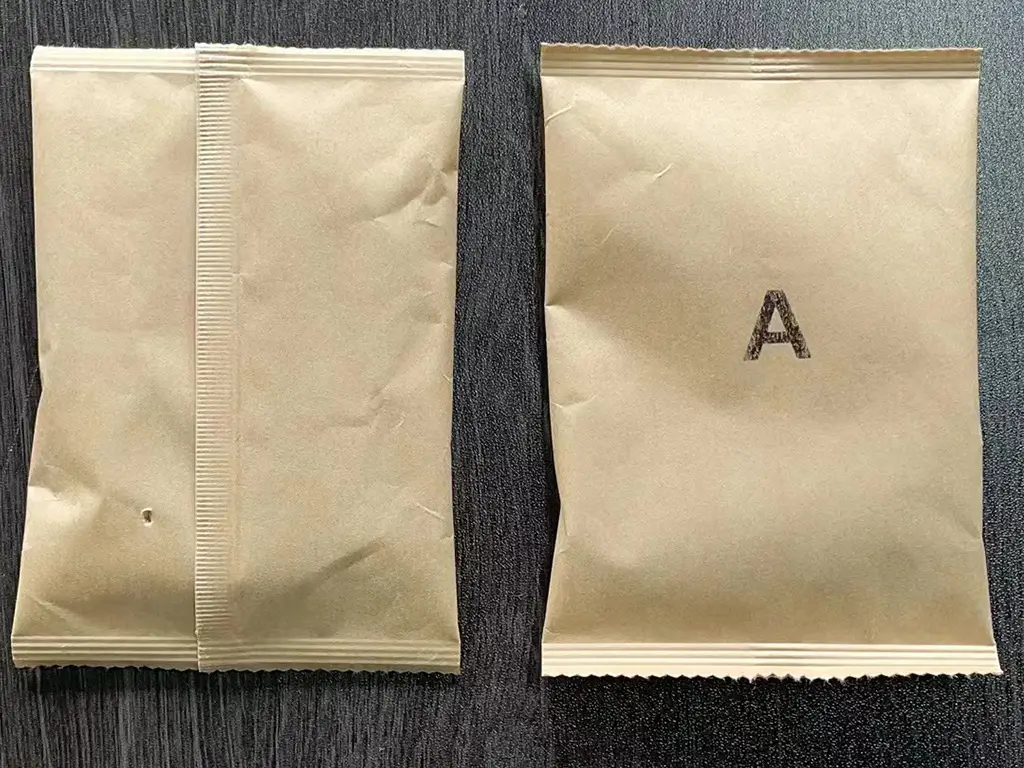

- Гибкие размеры мешков: Обрабатывает сумки длиной 50-300 мм и шириной 50-300 мм, подходит для малых и средних комплектов.

- Универсальные материалы: Совместим с упаковочными пленками OPP/CPP, OPP/CE, PET/PE и PE.

- Удобный для пользователя: Система управления PLC с сенсорным экраном и памятью рецептов.

- Экономически эффективный: Снижает зависимость от ручного труда, минимизирует количество ошибок и повышает общую эффективность.

- Сильная поддержка питания: Оснащен системой питания мощностью 5 кВт для стабильной и непрерывной работы.

Применимые отрасли и сценарии

- Промышленность: Производство метизов, крепежа, мебельной фурнитуры, автомобильных компонентов, логистика и дистрибуция.

- Сценарии:

- Смешанная упаковка винтов, гаек, болтов, шайб и других мелких деталей.

- Подготовка комплекта для сборки мебели.

- Розничная упаковка DIY с несколькими спецификациями в одном пакете.

- Замена ручных операций подсчета при крупносерийном производстве.

Технические характеристики

| Модель | FY-520 |

| Скорость упаковки | 10-60 мешков/мин |

| Материал упаковки | OPP/CPP, OPP/CE, PET/PE, PE |

| Размер упаковки | L 50-300 мм; W 50-300 мм |

| Тип упаковки | Смешанный / Одиночный / Купе |

| Счетная емкость | 5-40 шт/мешок |

| Источник питания | AC220V-380V / 50-60Hz / 5KW |

Рабочий процесс

Подача нескольких типов оборудования → Вибрационная подача в чашу → Подсчет → Цепной ковшовый конвейер → Формирование пакетов → Загрузка продукции → Запечатывание → Печать/маркировка → Выпуск готовых пакетов

Возможности настройки и расширения

- Дополнительные виброчаши для увеличения количества SKU и производительности.

- Опциональная печать и маркировка пакетных кодов, штрих-кодов и QR-кодов.

- Интеграция с контрольными весами и браковочной станцией.

- Подключение ERP/MES для приложений "умной фабрики".

- Полное расширение производственной линии с помощью картонных или боксерских машин.

Случаи применения

- Аппаратный завод: Автоматизированная упаковка болтов, гаек и шайб в смешанные комплекты для экспорта.

- Поставщик мебели: Упаковка петель, винтов и направляющих в один комплект для монтажных пакетов.

- Логистический центр: Высокоскоростная упаковка индивидуального ассортимента оборудования для заказов электронной коммерции.

Послепродажное обслуживание

- Установка и ввод в эксплуатацию: Услуги по удаленному или выездному вводу в эксплуатацию.

- Гарантия: 12 месяцев стандартной гарантии с поддержкой запасными частями.

- Техническая поддержка: круглосуточная помощь по телефону/электронной почте и устранение неполадок.

- Обучение операторов: Обеспечивает бесперебойный запуск производства.

- Поставка запасных частей: Всегда в наличии быстроизнашивающиеся детали.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

В: Может ли эта машина упаковать в одну сумку несколько предметов фурнитуры?

О: Да, он предназначен для упаковки смешанного типа и поддерживает несколько разновидностей оборудования в одном пакете.

В: Какова типичная производительность одного мешка?

A: Он может обрабатывать 5-40 штук на мешок, в зависимости от размера детали и конфигурации мешка.

В: Какие упаковочные материалы можно использовать?

A: Совместим с пленками OPP/CPP, OPP/CE, PET/PE и PE.

В: Подходит ли он для комплектов мебельной фурнитуры?

A: Да, он широко используется для изготовления комплектов мебельной фурнитуры, включая петли, направляющие, винты и гайки.