Product Overview

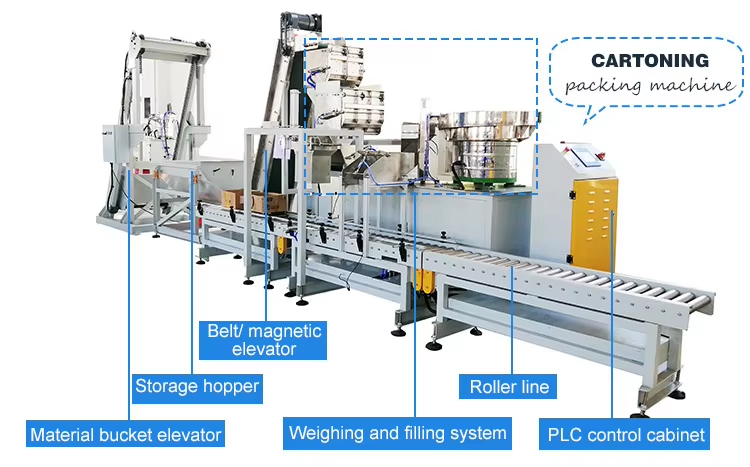

The Fastener Cartoning Machine (Model: FY-ZX) is specially designed for screws, nails, nuts, washers, stamping parts, and other regular-shaped products. It ensures accurate weight and count for each carton (5–25kg) and supports fully automated processes including carton opening, filling, sealing, and strapping. This machine significantly improves efficiency, reduces manual labor, and guarantees packaging accuracy.

Key Features & Advantages

- Suitable for various regular-shaped products including screws, nails, nuts, washers, and stamped parts.

- Accurate weighing and counting ensures correct quantity and weight per box.

- Fully automatic operation: box opening, measuring, filling, sealing, and packing.

- Optional labeling and coding: capable of box labeling and inkjet printing.

- Efficient and reliable: industrial-grade design for stable long-term operation.

- Easy to operate with PLC control system.

Applicable Industries & Scenarios

- Industries: Hardware manufacturers, fastener distributors, industrial parts suppliers.

- Scenarios:

- Monthly packaging of single-product boxes weighing 5–25kg.

- High-volume cartoning lines requiring accurate weight and counting.

- Automated production lines needing integrated filling, sealing, and labeling.

Technical Specifications

| Model | FY-ZX |

| Measurement Range | 5–25kg/box |

| Packing Speed | 3–5 boxes/min |

| Power Supply | AC220V / 50Hz / 2KW |

Workflow

Box feeding → Automatic box opening → Weighing & counting → Product filling → Automatic sealing → Packing → Optional labeling/inkjet printing → Finished box output

Customization & Expansion Options

- Adjustable weighing range for different box weights.

- Optional labeling or inkjet printing for batch codes or product information.

- Integration with conveyors for continuous automated production.

- Compatible with different box sizes and materials.

- Optional magnetic sorting module: ensures proper arrangement of nails or similar products according to customer requirements.

Application Cases

- Hardware Manufacturer: Automatic cartoning of screws, nails, and nuts for wholesale or retail.

- Industrial Supplier: Accurate weight boxes for e-commerce orders and distribution.

- Fastener Distributor: Automated cartoning to reduce labor and improve efficiency.

After-Sales Service

- Installation & commissioning: On-site or remote support.

- Warranty: 12-month standard warranty with spare parts support.

- Technical support: 24/7 online or phone assistance.

- Operator training: Provided along with operation and maintenance manuals.

- Spare parts supply: Fast delivery for common wear parts.

FAQ

- Q: What product types can this machine handle?

A: Screws, nails, nuts, washers, stamped parts, and other regular-shaped products. - Q: What is the typical box weight range?

A: 5–25kg per box. - Q: Can it automatically seal and label boxes?

A: Yes, the machine supports automatic sealing and optional labeling/inkjet printing. - Q: Can the machine arrange nails or similar products in a specific order?

A: Yes, an optional magnetic sorting module can be added to meet this requirement. - Q: What is the packing speed?

A: 3–5 boxes per minute depending on product and box size.