Product Overview

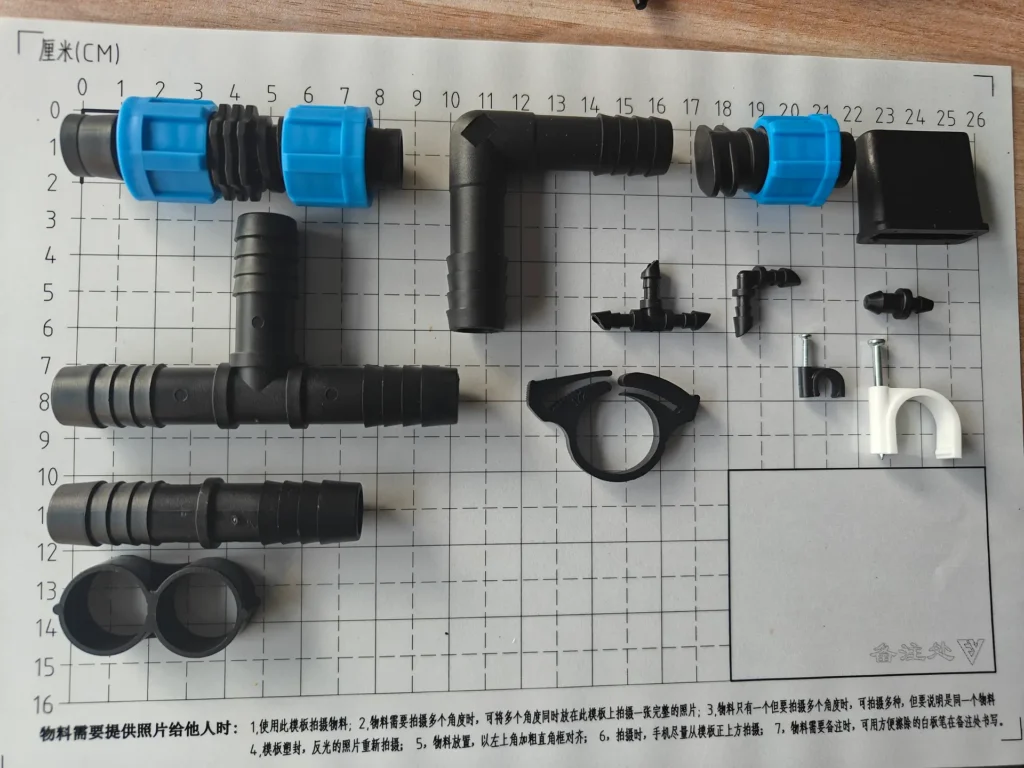

The Drip Irrigation Fittings Counting Packing Machine is specially designed for automatic counting and bagging of plastic fittings used in irrigation systems. It can handle a wide range of small components—such as drip connectors, tees, elbows, couplers, and end caps—ensuring each bag contains the correct quantity.

This machine is widely used by irrigation system manufacturers, plastic parts suppliers, and agricultural equipment distributors. It automates the entire packaging process, significantly improving productivity and consistency.

Key Features & Advantages

Accurate Counting:

Equipped with high-precision optical sensors or weighing systems to ensure every bag contains the correct number of parts.

Versatile Packaging:

Supports multiple bag sizes and can package up to 1–40 types of fittings in one bag.

Smart Control System:

PLC touch screen with multi-language interface (English, Spanish, Arabic, Chinese, etc.) for easy operation.

Durable Construction:

Made of stainless steel with an anti-corrosion surface—ideal for plastic and agricultural parts.

Flexible Configuration:

Bag length, count quantity, and sealing temperature can be freely adjusted to meet production needs.

Automatic Printing (Optional):

Can print product information, date, or barcode on each bag.

Applicable Industries & Scenarios

Industries:

- Drip irrigation fittings manufacturers

- Agricultural irrigation system producers

- Plastic component suppliers

- Agricultural product distributors

Application Examples:

- Irrigation system factory: Automatic packaging of drip connectors and tees.

- Agricultural supplier: Mixed bag packaging for installation kits.

- Plastic fittings manufacturer: Accurate counting and packaging for wholesale distribution.

Technical Specifications

| Model | FY-520 |

| Packing Speed | 10–60 bags/min |

| Packing Material | OPP/CPP, OPP/CE, PET/PE, PE |

| Packing Size | L 50–300 mm; W 50–300 mm |

| Packing Type | Mixed / Single / Compartment |

| Counting Capacity | 5–40 pcs/bag |

| Power Supply | AC220V–380V / 50–60Hz / 5KW |

Workflow

Feeding of drip fittings → Automatic counting/weighing → Bag forming → Product filling → Sealing and printing (optional) → Finished bag output

Customization & Expansion Options

- Adjustable bag size and count settings

- Compatible with weighing or vibrating feeding systems

- Optional automatic boxing or labeling modules

- Can be integrated with a full packaging line or conveyor

Application Cases

- Irrigation Parts Factory A: Achieved 40% increase in packaging efficiency for connectors and tees.

- Plastic Fittings Manufacturer B: Reduced manual labor by 3 operators through automation.

- Agricultural Supplier C: Created custom mixed bags for irrigation kits with consistent quality.

After-Sales Service

Installation & Commissioning:

Remote video guidance or on-site technician support.

Warranty:

12 months warranty, lifetime technical support.

Spare Parts Supply:

Common wear parts are available in stock for quick delivery.

Service Response:

24/7 technical assistance to ensure stable production.

FAQ

Q: Can this machine pack different types of fittings in one bag?

A: Yes, it can pack 1–40 kinds of fittings in each bag with precise counting.

Q: Can the machine print labels or codes?

A: Yes, it supports date and barcode printing (optional).

Q: What bag materials can it use?

A: It supports PP/CPP, PA/PE, PET/PE, and PE composite films.

Q: Is the counting accuracy stable for irregularly shaped fittings?

A: Yes, the system can be customized with suitable feeding and sensor modules for different shapes.