Automatic Screw Counting Packaging Machine

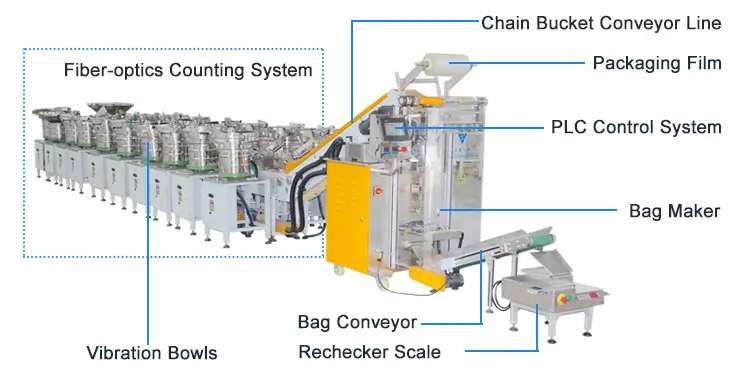

Automatic screw packaging machine (model: FY-420C) is a multi-functional screw packing machine designed for screws, nuts, bolts, fasteners, and other small hardware components. This automatic hardware packing solution integrates counting, weighing, bag making, sealing, and labeling, delivering high precision, high efficiency, and cost savings for industrial screw and hardware packaging applications.

Key Features & Advantages

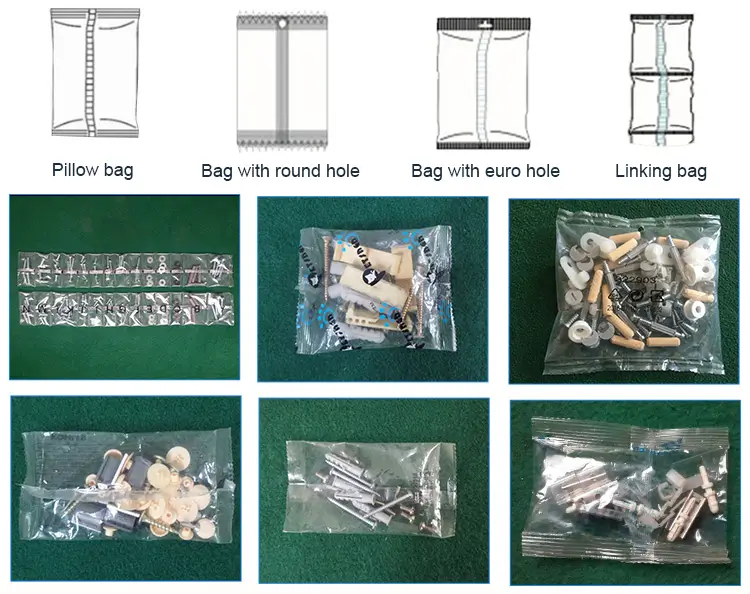

- Automatic counting & packaging for screws and hardware parts: 1–20 pcs per bag, up to 30 types per bag

- Flexible packaging modes: Supports mixed hardware kits, single screw packaging, and compartmentalized packing

- High-speed output: 10–60 bags per minute depending on screw or hardware type

- Wide film compatibility: Works with PP/PA/PE/CPP/PET for various screw and fastener packaging applications

- Customizable bag sizes: L 50–300mm, W 50–200mm

- Stable operation: PLC control system with simple, intuitive interface

- Durable construction: Built for long-term industrial hardware packing

Applicable Industries & Scenarios

Industries: Hardware manufacturing, furniture fittings, plastic components, logistics.

Scenarios:

- Packaging screws and fittings for furniture kits using an automatic screw packaging machine

- Preparing mixed fastener kits for retail or wholesale

- High-speed hardware packaging for industrial production lines

Technical Specifications

| Model | FY-420C |

| Packing Speed | 10–60 bags/min |

| Packing Material | PP/PA/PE/CPP/PET |

| Packing Size | L: 50–300mm, W: 50–200mm |

| Packing Type | Mixed / Single / Compartment |

| Counting Capacity | 1–20 pcs/bag; 1–30 kinds/bag |

Workflow

Feeding materials → Vibratory bowl feeding → Counting → Bag forming → Product loading → Sealing → Printing/labeling (optional) → Finished bag output

Customization & Expansion Options

- Multiple vibratory bowls for different product types.

- Optional printing and labeling (barcode, QR code, batch info).

- Integration with checkweigher for precise quality control.

- Conveyor system for automated collection of finished bags.

- Custom bag sizes and film types for specific applications.

Application Cases

- Furniture Manufacturer: Packaging screws, bolts, and fittings for flat-pack furniture.

- Hardware Supplier: Preparing mixed kits of fasteners for wholesale or retail.

- Logistics Provider: Automated bagging for order fulfillment and distribution.

After-Sales Service

- Installation & commissioning: On-site setup or remote guidance.

- Warranty: 12-month standard warranty with spare parts supply.

- Technical support: 24/7 online and phone service.

- Training: Operator training and manuals provided.

- Spare parts supply: Fast replacement for common wear parts.

FAQ

Q: Can this screw packing machine handle multiple product types per bag?

A: Yes, it supports single, mixed, and compartment hardware packaging modes.

Q: What is the typical packing speed of this automatic hardware packing machine?

A: 10–60 bags per minute depending on product size and configuration.

Q: What is the maximum number of types per bag?

A: It can package up to 30 different types per bag.

Q: Which films can be used?

A: Compatible with PP, PA, PE, CPP, and PET films.