Fastener packaging machines are revolutionizing the manufacturing world. They automate the packaging process, reducing manual labor and increasing speed.

These machines handle a variety of fasteners, including screws, bolts, and nuts. This versatility makes them indispensable in many industries.

Consistency and accuracy are key benefits of fastener packaging equipment. They minimize errors, ensuring each package meets quality standards.

Automation in packaging leads to significant cost savings over time. Businesses can allocate resources more efficiently, boosting their bottom line.

Fastener packaging lines can be customized to meet specific production needs. This flexibility allows companies to adapt to changing demands.

Auto fastener packaging machines integrate seamlessly with existing production lines. They enhance workflow without disrupting current operations.

Safety is another advantage. These machines reduce the need for manual handling, improving workplace safety.

Fastener packaging machines are equipped with advanced technology for precise counting and sorting. This precision enhances product quality and presentation.

Understanding Fastener Packaging Machines

Fastener packaging machines are key to efficient manufacturing. They automate the otherwise manual process of packaging small but essential items.

The technology behind these machines is advanced. It allows for precise handling and packaging of fasteners with minimal human intervention.

These machines perform various functions. They count, sort, and package fasteners quickly and accurately. This reduces the chance of human error.

Different types of fasteners, such as screws, nuts, and bolts, can be processed. This versatility makes them valuable assets in diverse manufacturing sectors.

Key features of fastener packaging machines include:

- Speed and efficiency: Handling large volumes quickly.

- Accuracy: Reducing errors with precise counting.

- Versatility: Accommodating different fastener types.

Investing in these machines can significantly boost productivity. They offer a high return on investment through efficiency gains.

Understanding their operation can highlight how they fit into a broader manufacturing system. This knowledge helps companies maximize their use.

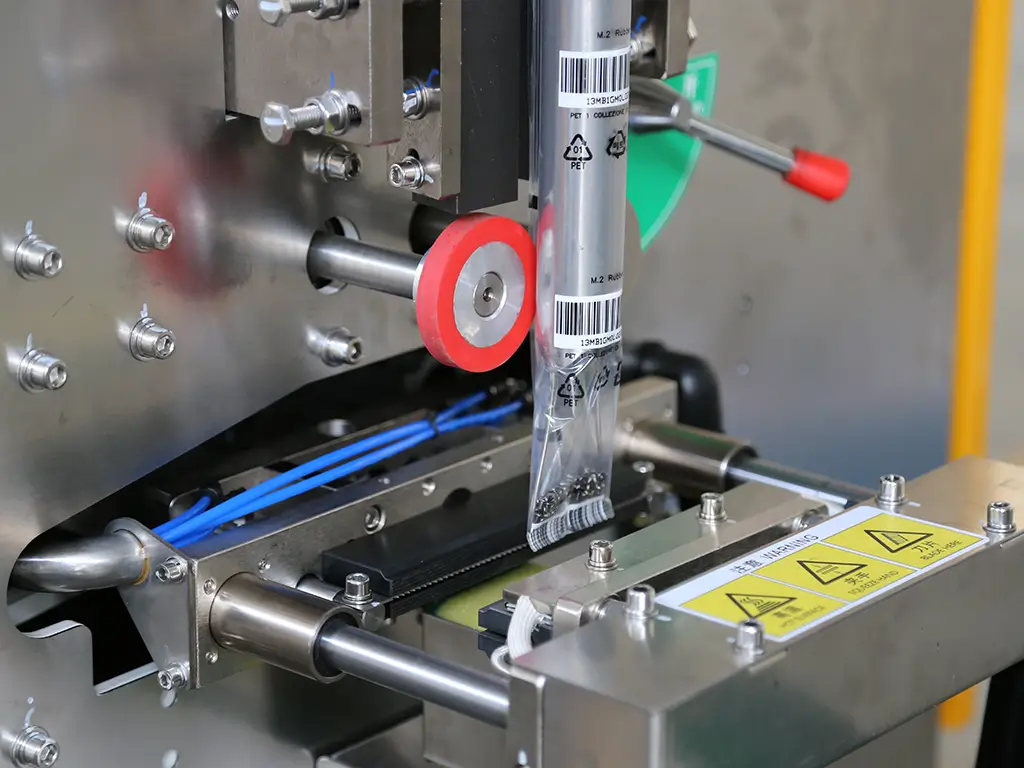

Key Components of a Fastener Packaging Line

A fastener packaging line consists of several crucial elements. Each component plays a specific role in ensuring the line operates smoothly.

One key element is the feeder system. It guides fasteners from bulk supply into the machine for sorting and counting.

Counting mechanisms are essential as well. These devices accurately tally the fasteners, ensuring precise package contents every time.

The packaging module shapes and fills the packages. It also seals them to ensure product integrity and quality.

Conveyor belts are also part of the system. They transport packaged products from one section to another efficiently, minimizing manual handling.

Quality control systems check the packages. They ensure only correctly packed products move forward. This reduces waste and ensures quality.

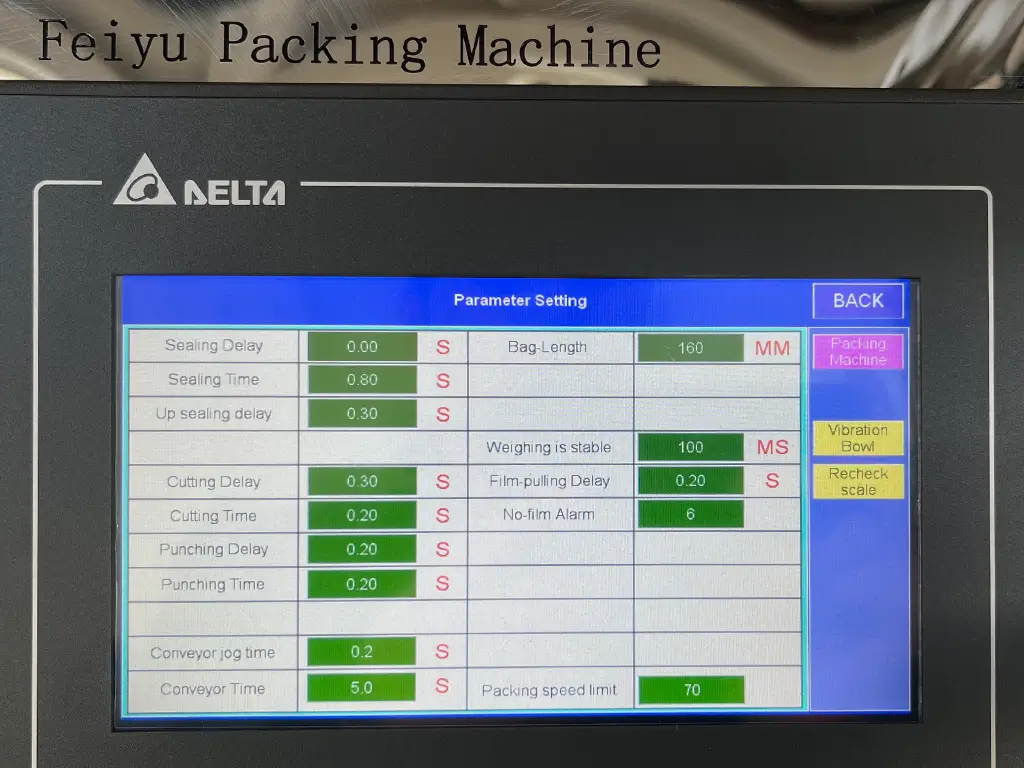

Control systems manage the overall packaging line operation. They coordinate the components and allow user adjustments.

Key components include:

- Feeder systems

- Counting mechanisms

- Packaging modules

- Conveyor belts

- Quality control systems

- Central control systems

Together, these components form a seamless, efficient packaging operation. Each part integrates into a unified line, streamlining production.

Types of Fastener Packaging Equipment

Fastener packaging equipment varies in design and function. Various types cater to different production needs.

Form, Fill, and Seal machines are common in packaging. They form packages, fill them with fasteners, and seal them tightly.

Counting machines are specialized for precise counting. They ensure the exact quantity of fasteners goes into each package.

Another type is the bagging machine. It efficiently fills bags with fasteners, ideal for bulk packaging.

Case packers are used for larger shipments. They pack multiple small packages into boxes or cases.

Vibratory bowl feeders are integral in many setups. They feed fasteners into the machine consistently and smoothly.

Automated equipment can be customized. This flexibility allows adaptation to specific product and package requirements.

Common fastener packaging equipment types include:

- Form, Fill, and Seal machines

- Counting machines

- Bagging machines

- Case packers

- Vibratory bowl feeders

Each machine type enhances part of the packaging process. Businesses select equipment based on their particular operational goals.

Innovative designs in these machines continually emerge. They promise more efficiency and versatility in packaging solutions.

How Automation Transforms Fastener Packaging

Automation has revolutionized fastener packaging. By minimizing manual handling, it streamlines the entire process.

Automated systems boost efficiency. They drastically reduce the time needed to package fasteners.

These systems ensure accuracy and precision in packaging. The right number of fasteners are packed every time.

Consistent packaging quality is a major benefit. It improves product appeal and customer satisfaction.

Labor costs drop significantly with automation. Fewer workers are needed to monitor and manage the process.

Safety in the workplace sees marked improvements. Automation lessens the need for manual handling, reducing injury risks.

Key automation benefits include:

- Increased speed and efficiency

- Enhanced accuracy and precision

- Consistent packaging quality

- Reduced labor costs

- Improved safety

Additionally, automated systems often lead to material savings. They optimize the use of packaging materials, reducing waste.

Automation in fastener packaging is no longer optional. It is essential for competitiveness and operational excellence.

Benefits of Using Auto Fastener Packaging Machines

Auto fastener packaging machines offer numerous advantages. Their impact on efficiency and cost-effectiveness is significant.

Firstly, these machines handle high volumes effortlessly. This capability is crucial for large-scale operations.

They ensure speed in the packaging process. Rapid packaging means shorter production cycles.

Another advantage is precision. Machines accurately count and sort fasteners, avoiding costly mistakes.

With automation, product consistency improves. Every package meets the same quality standards.

Auto machines contribute to significant labor savings. Less manual intervention is needed.

They also enhance workplace safety. Fewer manual tasks reduce injury risks.

Key benefits of auto fastener packaging machines include:

- Handling high volumes with ease

- Faster packaging times

- Enhanced precision and accuracy

- Improved product consistency

- Labor savings

- Increased workplace safety

Furthermore, these machines often include advanced features. They support various packaging sizes and formats, offering flexibility.

Investing in such technology yields long-term financial benefits. Lower labor costs and reduced waste contribute to higher profitability.

Auto fastener packaging machines are an integral part of modern manufacturing. They allow businesses to remain competitive while delivering consistent quality.

Customization and Flexibility in Fastener Packaging Lines

Fastener packaging lines can be tailored to meet specific needs. This customization boosts efficiency and functionality.

Manufacturers require different packaging solutions. Adjustable machines cater to diverse product specifications.

Flexibility in packaging lines means adapting to changes. Manufacturers can shift production focuses quickly.

Adaptable machines handle various fastener types. Screws, bolts, and nuts can all be processed seamlessly.

Switching between packaging formats is simple. Machines support different sizes and shapes for optimal versatility.

Customization options in fastener packaging lines include:

- Adjustable settings for various fastener types

- Compatibility with multiple packaging materials

- Modular components for easy updates

- Software integration for precision control

This flexibility aids in maintaining high production standards. Businesses can respond to market demands swiftly and efficiently.

Ultimately, customizable lines offer a competitive edge. They enable manufacturers to innovate and adapt without major overhauls.

Investing in flexible packaging solutions supports long-term growth. The ability to modify and upgrade ensures future readiness.

Integration with Production and Inventory Systems

Integrating fastener packaging machines into production systems streamlines operations. These machines can sync with existing setups, enhancing workflow efficiency.

Inventory management benefits from integration as well. Real-time data tracking provides insightful stock control, preventing overstock or shortages.

Systems integration allows for seamless data flow. This results in better decision-making based on accurate inventory levels.

Automated synchronization reduces manual errors. By linking machines to inventory systems, businesses ensure consistent data across departments.

Key integration benefits include:

- Enhanced inventory tracking and management

- Reduced manual input and potential errors

- Improved data accuracy for strategic planning

- Streamlined production processes for higher efficiency

The technology supports cohesive system operations. Fastener packaging machines contribute to smoother transitions within production environments.

Leveraging integration, companies boost productivity. Coordinating systems optimizes resources, leading to cost savings and better performance.

Businesses that embrace integrated solutions stay competitive. The synergy between packaging and inventory is crucial for modern operations.

Improving Safety and Reducing Labor Costs

Fastener packaging machines enhance workplace safety. They automate tasks that would otherwise require manual effort, reducing worker injuries.

Automation minimizes repetitive strain injuries. These machines perform tasks consistently, lowering the risk of human error and associated accidents.

Companies benefit from reduced labor costs. With machines handling packaging, fewer manual workers are needed for the same tasks.

Reducing manual labor means focusing resources elsewhere. Employees can engage in more complex and rewarding tasks, boosting job satisfaction.

Safety and Cost Benefits:

- Lower risk of workplace injuries

- Fewer workers needed for packaging tasks

- Reduced strain-related health issues

- Employees focus on higher-value activities

Automated systems foster a safer environment. The reduction in direct human involvement decreases potential hazards.

Investing in fastener packaging machines pays off. Businesses not only save money but also create a safer workspace.

Enhancing Product Quality and Packaging Consistency

Fastener packaging machines enhance product quality. They ensure every fastener is perfectly packaged, maintaining high standards.

Packaging consistency is crucial for brand reputation. These machines guarantee uniformity in every package, enhancing consumer trust.

Precision is a key feature of these machines. They count and sort fasteners meticulously, minimizing errors that affect product quality.

Automation also leads to fewer defects. By reducing human error, machines improve the overall integrity of the packaging process.

Quality and Consistency Benefits:

- Uniform package appearance

- Accurate fastener counts

- Minimized packaging defects

- Improved brand reliability

Consistent packaging results in better customer satisfaction. Buyers receive neatly packaged, well-counted fasteners every time.

Machines also optimize the use of materials. They reduce waste, ensuring that every package meets company standards.

by Marek Ruczaj (https://unsplash.com/@marek_ruczaj)

Choosing the Right Fastener Packaging Equipment for Your Needs

Selecting the appropriate fastener packaging equipment is crucial. It impacts your production efficiency and overall business operations.

Begin by assessing your specific packaging requirements. Different machines offer varied capabilities tailored to unique demands.

Consider the volume of fasteners you need to package regularly. High-volume operations require machines that support large-scale production.

Budget constraints also play a significant role. Investment costs should align with expected returns and long-term benefits.

Key Factors to Consider:

- Production volume

- Budget considerations

- Customization needs

- Integration with existing systems

Customizable features can address specific packaging sizes or formats. Ensure the machine can adapt to future requirements and technology upgrades.

Evaluate the ease of integration with your current systems. Seamless integration boosts productivity and reduces disruption during installation.

Future Trends in Fastener Packaging Technology

The future of fastener packaging is promising. Emerging technology offers exciting advancements in efficiency and precision.

Automation will become even more sophisticated. Machines will feature AI and machine learning for enhanced decision-making.

Sustainability is another key trend. Expect innovations that minimize material waste and boost eco-friendly practices.

Emerging Trends in Fastener Packaging:

- Advanced automation with AI integration

- Sustainable packaging solutions

- Improved precision and accuracy

- Enhanced connectivity for real-time monitoring

Connectivity will also improve. IoT-enabled machines can facilitate real-time monitoring and data analysis.

These advancements will empower manufacturers to stay competitive. Embracing these trends can lead to greater efficiency and reduced costs.

Conclusion: Maximizing Efficiency with Fastener Packaging Machines

Fastener packaging machines are revolutionizing industrial operations. Their integration leads to significant efficiency gains for manufacturers.

Automation reduces errors and speeds up processes. This results in higher productivity and better use of resources.

Fastener packaging equipment is a smart investment. It boosts not only efficiency but also improves product quality and consistency.

Embracing these machines ensures competitiveness in today’s market. They pave the way for streamlined operations and satisfied customers.