Envasadora contadora de cierres con 6 alimentadores vibratorios de bol

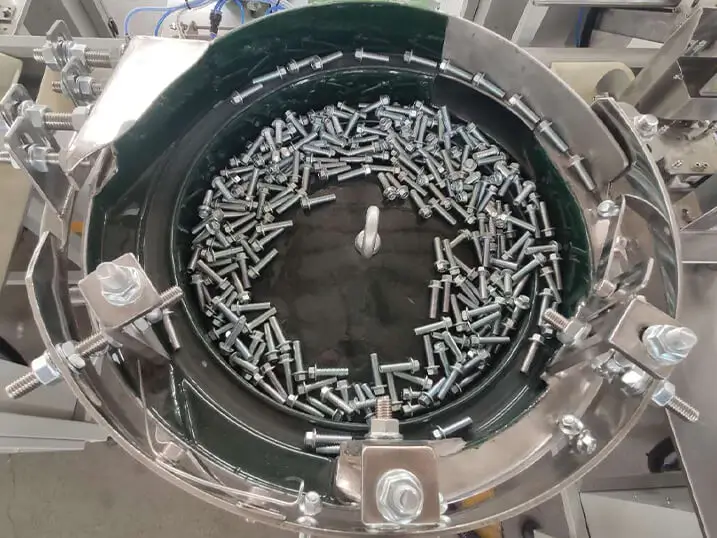

Nuestra envasadora contadora de elementos de fijaciónCon 6 cubetas utiliza una avanzada tecnología de recuento de varias cubetas y está diseñada para el envasado eficiente y preciso de tornillos, tuercas, arandelas y otros elementos de ferretería. Mejora la eficiencia de conteo y empaquetado de la línea de producción a través de 6 cubetas de conteo independientes que trabajan simultáneamente, y es especialmente adecuada para escenarios en los que es necesario empaquetar varias especificaciones de productos al mismo tiempo. Tanto si se trata del envasado de un producto de una sola especificación como del envasado mixto de múltiples especificaciones de productos, esta máquina puede satisfacer sus necesidades y garantizar la precisión y consistencia del envasado.

Capacidad de envasado con múltiples especificaciones

Esta máquina admite el envasado de productos de diferentes especificaciones al mismo tiempo. A través de 6 cuencos de conteo, puede mezclar y empaquetar tornillos u otros herrajes de diferentes especificaciones, y cada paquete contiene múltiples productos para satisfacer las complejas necesidades de empaquetado.

Aplicación

- Fabricación de hardware: recuento y envasado automáticos de tornillos y tuercas de diversas especificaciones mediante una máquina llenadora de tornillos.

- Industria electrónica: recuento y embalaje precisos de componentes y piezas electrónicas.

- Autopartes: envasado automático de pequeñas piezas de automóvil con una envasadora de bolsas de rosca.

- Otros: adecuado para las necesidades de recuento y envasado de diversas piezas pequeñas.

Modelo

| Modelo | FY-240A | FY-420A |

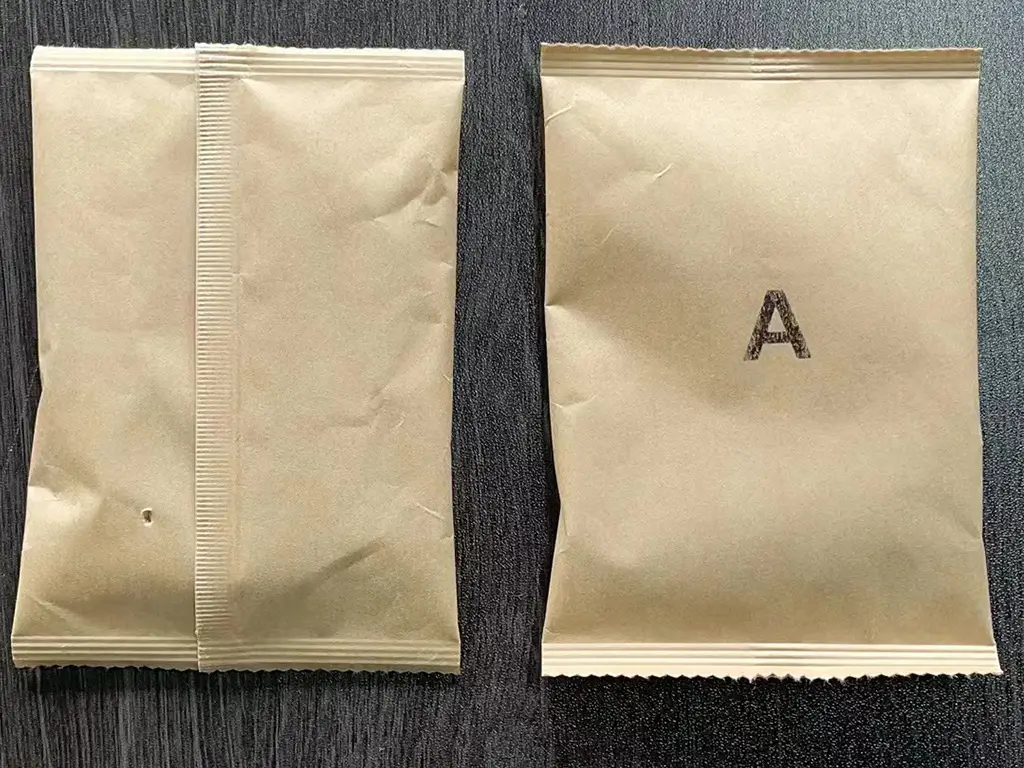

| Tamaño del embalaje | L: 30-180 mm, A: 50-140 mm | L: 50-300 mm, A: 50-200 mm |

| Anchura máxima de la película | 300 mm | 420 mm |

| Material de embalaje | PP/CPP,PA/PE,PET/PE,PE | |

| Capacidad de recuento | 1-20 unidades/bolsa; 1-6 tipos/bolsa | |

| Velocidad de envasado | 10-50 bolsas/min | |

| Potencia | AC220V/50-60Hz/2kW | |

| Tamaño de la máquina | 1500mm(Largo)* 1200mm(Ancho)* 1650mm(Alto) | |

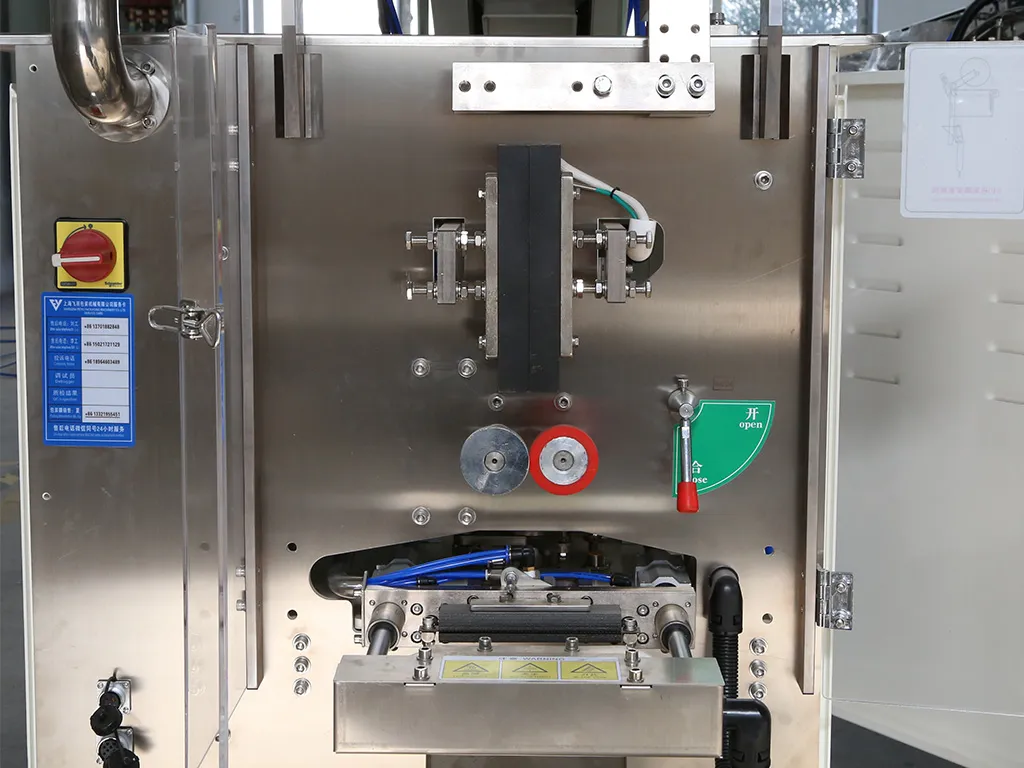

Composición de la máquina

Sistema de recuento sincronizado de seis cubetas

Equipada con cuatro cubetas de recuento independientes, cada cubeta puede contar de forma independiente y procesar tornillos, tuercas u otros elementos de fijación de diferentes especificaciones al mismo tiempo según sea necesario. El método de trabajo de cuatro cubetas mejora significativamente la eficiencia y la velocidad de empaquetado y reduce el tiempo de producción.

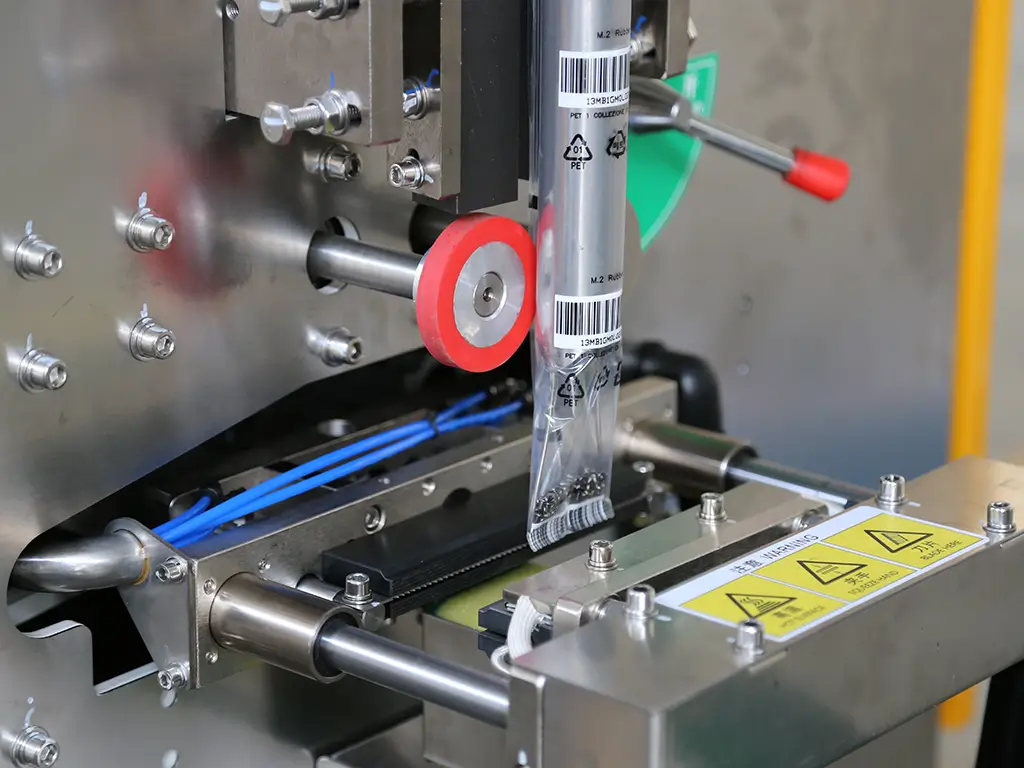

Recuento preciso y sellado automático de bolsas

Mediante un sistema de recuento de fibra óptica de alta precisión, cada recipiente puede contar con exactitud cada tornillo, tuerca y otros pequeños elementos de fijación para garantizar el número correcto de cada paquete. Al mismo tiempo, la máquina completará automáticamente las operaciones de llenado y sellado de bolsas sin intervención manual, reduciendo la tasa de error.