In today’s fast-paced manufacturing world, efficiency is key. Screw packaging machines offer a solution to streamline operations. These machines automate the packaging of screws and fasteners, saving time and reducing errors.

They are versatile, handling various screw sizes and types. This adaptability makes them suitable for many industries. From automotive to electronics, these machines meet diverse needs.

Cost savings are another benefit. By reducing manual labor, businesses can lower expenses. This leads to increased profitability over time.

Screw packaging machines also enhance accuracy. Consistent packaging quality ensures customer satisfaction. This reliability can boost a company’s reputation.

Integration into existing production lines is seamless. This improves workflow and boosts overall productivity. Advanced features like touch-screen controls make them user-friendly.

Sustainability is a growing concern. These machines help by reducing material waste. They also support energy-efficient practices.

Investing in a screw packaging machine is a smart move. It offers long-term benefits and keeps businesses competitive.

What Is a Screw Packaging Machine?

A screw packaging machine is a specialized device designed to automate the process of packaging screws and fasteners. It efficiently manages the packing of a wide range of screws, ensuring uniformity and precision.

These machines are integral to packaging lines, often tailored to handle different screw sizes and types. This adaptability makes them indispensable to diverse industries, from construction to furniture manufacturing.

A typical screw packaging machine consists of several key components. These include hoppers for screw storage, feeding mechanisms, and sealing systems. Together, they facilitate seamless operation without manual intervention.

In addition to speed and precision, these machines minimize human error. Automated counting ensures each package meets required specifications, thus enhancing quality control.

Operators benefit from intuitive interfaces, often with touch-screen controls. This ease of use reduces training time and improves overall efficiency. In modern setups, integration with production lines enables real-time monitoring and adjustments.

Overall, a screw packaging machine elevates operational efficiency. It is a worthwhile investment for businesses aiming to enhance productivity and maintain high-quality standards.

Key Components and Working Principle

Screw packaging machines are complex yet efficient devices, each part contributing to the smooth packaging process. The primary components work in harmony to ensure maximum productivity.

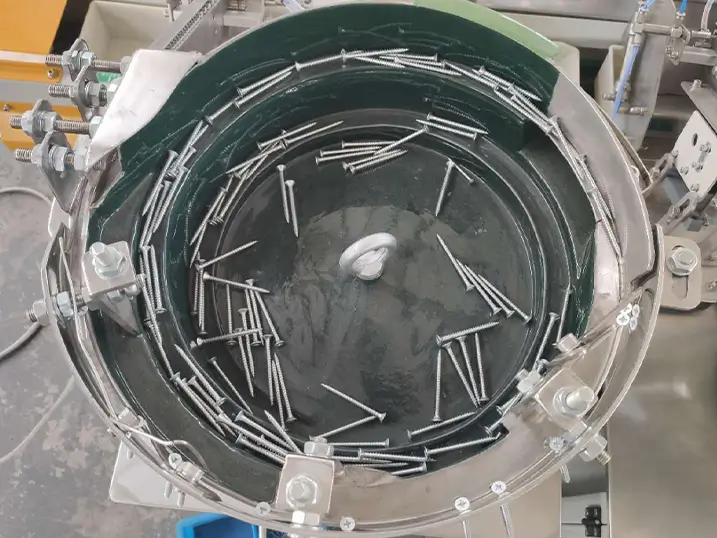

First, the screw hopper is pivotal. This component stores screws in bulk before they enter the packaging system. Advanced hoppers often include agitators to prevent screws from clumping together.

Next, the feeder mechanism plays a crucial role. It transports screws from the hopper to the sorting system. This ensures continuous flow without jams, which is vital for high-speed operations.

Then, the counting system precisely counts screws. With sensors and software, it ensures every package contains the correct number of screws. This accuracy is essential for maintaining quality standards.

After counting, the filling system moves screws to containers or bags. This step is highly automated to guarantee precision and speed. Proper filling reduces waste and enhances efficiency.

Finally, the sealing mechanism secures the packaging. It ensures that screws are tightly and safely packed, preventing spillage during transport. Sealing is achieved through various methods, such as heat sealing or adhesive applications.

Additionally, user interfaces, often touch-screen, offer easy control and monitoring. This human-machine interaction is crucial for quick adjustments and troubleshooting.

Overall, the synergy of these components underpins the screw packaging machine’s effectiveness. It delivers seamless operation and high-quality packaging results every time.

Types of Screw Packaging Machines

Screw packaging machines come in various types, each designed to meet specific packaging needs. Understanding these types can aid in selecting the right machine for your production requirements.

First, there are automatic screw packaging machines. These systems handle high-volume production with minimal human intervention. They are ideal for large manufacturing plants seeking efficiency.

Semi-automatic screw packaging machines offer a blend of automation and manual input. They suit businesses with moderate packaging demands, providing both flexibility and control.

Single-head machines focus on packing one type of screw at a time. They are compact and effective for small-scale production, where volume is not an issue.

Multi-head systems, on the other hand, can package different screw sizes simultaneously. They are perfect for diverse product lines, ensuring efficiency and versatility.

Vertical screw packaging machines optimize floor space. They are ideal for facilities with height limitations and high-volume output.

Horizontal packaging machines cater to long packaging solutions. They handle products that require horizontal alignment during the process.

Customizable machines offer tailored features for unique requirements. These allow for adjustments in packaging sizes and formats, enhancing product presentation.

Lastly, integrated packaging lines combine screw packaging with other processes such as labeling. They provide a seamless transition between packaging stages for comprehensive solutions.

In choosing a screw packaging machine type, consider your production goals and constraints. Matching the right type to your needs ensures enhanced productivity and cost-effectiveness.

Major Advantages of Screw Packaging Machines

Screw packaging machines provide numerous advantages for manufacturing industries. The primary benefit is increased efficiency and reduced manual workload. These machines can drastically enhance productivity by streamlining the packaging process.

Automation cuts down time spent on manual operations, leading to significant savings in labor costs. Companies can redirect human resources to more complex tasks, optimizing workforce utilization.

Accuracy and consistency are major strengths of these machines. They ensure every package meets quality standards, reducing errors commonly found in manual packaging.

Another key advantage is the machine’s ability to handle different types of screws. The versatility allows businesses to manage diverse product lines without multiple setups.

Material waste is minimized, as these machines use precise measurements. This supports sustainable practices by minimizing environmental impact and reducing packaging costs.

Screw packaging machines can integrate seamlessly into existing production lines. This compatibility enhances overall operational efficiency by providing a cohesive workflow.

Safety features included in these machines protect operators from potential hazards. This improves the working environment and reduces the risk of workplace injuries.

Technological advancements offer further benefits, such as real-time monitoring and data analysis. These capabilities enable manufacturers to make informed decisions quickly.

The machines support compliance with industry standards and regulations. This not only ensures product safety but also enhances brand reputation.

Overall, investing in screw packaging machines can significantly boost a company’s profitability and market competitiveness.

Increased Efficiency and Productivity

Screw packaging machines are synonymous with efficiency. They accelerate the packaging process, ensuring faster production cycles. This increase in speed allows companies to meet tight deadlines and manage peak demand effectively.

Key features contributing to higher productivity include:

- High-Speed Operations: Machines can package thousands of screws per hour.

- Automatic Counting: Ensures precise quantities in every package.

- Integrated Systems: Combines multiple packaging stages into one process.

The machines reduce the need for manual counting and packaging, allowing companies to allocate their labor resources more strategically. As a result, production facilities can significantly boost their output without sacrificing quality.

The ability of these machines to sustain high-speed packaging also helps in maintaining product quality, as each screw is packaged consistently. This leads to fewer errors and reworks, further enhancing productivity.

In sum, screw packaging machines elevate productivity to new heights, allowing businesses to stay competitive in fast-paced markets.

Cost Savings and Reduced Labor

The economic benefits of screw packaging machines are substantial. They can dramatically lower labor expenses by automating tedious tasks that would otherwise require a large workforce.

Key ways these machines save costs include:

- Reduced Workforce Needs: Fewer hands are required, cutting down on wages.

- Less Material Waste: Automation optimizes the use of packaging materials.

- Decreased Error Rates: Fewer mistakes mean less money spent on corrections.

Automation also helps curb operational costs over time. Businesses save on employee training and lessen the impact of human error. Lower material waste further contributes to financial savings.

Long-term use of these machines can lead to impressive financial gains. Companies find increased ROI as initial investments pay off through continual cost-efficiency.

With these machines, businesses not only save money but also benefit from improved operations and competitiveness. The financial relief enables them to invest in other growth areas.

Enhanced Packaging Accuracy and Consistency

Screw packaging machines bring unparalleled accuracy to packaging operations. They use advanced technology to ensure precise counts and measurements, eliminating the errors typically found in manual packaging.

Benefits of enhanced packaging accuracy include:

- Consistent Quality: Every package meets established standards.

- Efficient Inventory Management: Exact counts streamline stock control.

- Reduced Returns: Minimized errors lead to better customer satisfaction.

The precision offered by these machines translates into reliable packaging outcomes. Businesses can rely on them for delivering consistent quality, even in high-volume production.

By maintaining tight control over packaging accuracy, companies can enhance their brand reputation. Customers receive products as expected, leading to higher satisfaction and loyalty.

Overall, these machines offer a robust solution for businesses aiming to maintain or improve quality standards while maximizing operational efficiency.

Flexibility and Customization

A distinct advantage of screw packaging machines is their flexibility. These machines can be customized to meet specific packaging needs, accommodating a range of screw sizes and types.

Customization options include:

- Adjustable Settings: Modify parameters for different products.

- Programmable Features: Store multiple configurations for seamless switching.

- Variety of Packaging Formats: Choose from bags, boxes, or blister packs.

This adaptability makes screw packaging machines an ideal solution for diverse manufacturing environments. Businesses can cater to unique customer preferences without extensive manual changes.

The machine’s flexibility extends to custom branding and labeling. Companies can enhance product presentations and align them with their marketing strategies.

Ultimately, this flexibility allows businesses to remain agile and responsive to market changes, driving growth and customer engagement.

Improved Safety and Ergonomics

Safety is paramount when operating machinery, and screw packaging machines are designed with this in mind. They come equipped with features that protect workers and optimize ergonomic conditions.

Key safety aspects of these machines include:

- Barrier Guards: Protect operators from moving parts.

- Emergency Shutoff Switches: Immediate response in case of malfunctions.

- Ergonomic Designs: Minimize strain during operation.

Ensuring a safe working environment is critical for maintaining high morale and productivity. Operators experience less fatigue, resulting in fewer accidents and injuries.

The safety and ergonomic features not only comply with regulatory standards but also provide peace of mind to businesses and employees alike.

In conclusion, screw packaging machines contribute to a secure and comfortable workplace, enhancing overall operational efficiency.

Integration with Screw Packaging Lines and Other Equipment

Screw packaging machines are designed for seamless integration into existing packaging lines. This capability enhances efficiency across the entire production process.

The integration process involves connecting the machine with other equipment to form a cohesive packaging line. This interconnected system streamlines the workflow, reducing bottlenecks and improving speed.

Key components that can be integrated with screw packaging machines include:

- Labeling Equipment: Ensures accurate branding and product information.

- Sealing Machines: Protects products by providing secure closures.

- Conveyor Systems: Moves products smoothly through the packaging line.

Combining these components with screw packaging machines creates a well-coordinated system. The entire line benefits from synchronized operations, maximizing production capacity.

Moreover, integrating these machines enhances data flow between systems. This connectivity allows for real-time performance monitoring and quicker adjustments.

Ultimately, integration with a comprehensive packaging line ensures that businesses can respond rapidly to changes in demand without sacrificing quality or efficiency.

Technological Advancements in Screw Packaging Machines

The screw packaging machine industry has evolved significantly with technological advancements. These innovations enhance both functionality and efficiency.

Modern machines now incorporate smart technology features. This allows for real-time data collection and monitoring, helping operators make quick, informed decisions.

A key advancement is the integration of the Internet of Things (IoT). IoT enables machines to communicate with other equipment, optimizing the entire packaging process.

Some cutting-edge features in contemporary screw packaging machines include:

- Touch-screen Controls: Simplifies machine operation with user-friendly interfaces.

- Automatic Counting Systems: Ensures precise quantities are packaged with minimal errors.

- Weight Checking Mechanisms: Verifies that each package meets set standards.

These technologies improve productivity by minimizing downtime and maintenance needs. They also allow for flexibility in packaging design and operations.

Moreover, advanced screw packaging machines are more energy-efficient. This reduces operational costs and supports sustainable production practices.

The continuous integration of technology into these machines ensures they remain an integral part of modern manufacturing processes. This not only boosts operational efficiency but also enhances product quality.

Applications Across Industries

Screw packaging machines are versatile, catering to diverse industry needs. This adaptability makes them indispensable in various sectors.

In the automotive industry, these machines facilitate efficient packing of essential fasteners. The accuracy and speed they offer are key to maintaining production lines.

Construction companies also benefit from these machines. Packing screws and bolts quickly helps meet tight project timelines.

by François Hurtaud (https://unsplash.com/@francoishurtaud)

Electronics manufacturers use them to pack small components securely. This helps protect sensitive parts during transit and boosts assembly line efficiency.

The furniture industry also relies on screw packaging machines. Rapid packaging of fasteners ensures products reach customers complete and ready for assembly.

Industries that use screw packaging machines include:

- Automotive

- Construction

- Electronics

- Furniture

- Consumer goods

Each of these sectors leverages the technology to boost productivity and ensure product quality. By employing screw packaging machines, industries streamline their supply chains. This technological investment pays off through improved operations and customer satisfaction.

How to Choose the Right Screw Packaging Machine

Selecting the right screw packaging machine is crucial for optimizing operations. Consider your production needs and the type of screws you process.

Begin by assessing the variety and volume of screws you package. Machines vary in capabilities, handling different sizes and quantities efficiently.

Evaluate the machine’s integration potential. It should fit seamlessly into your existing production line to enhance overall workflow efficiency.

Cost considerations are also critical. Weigh the upfront investment against long-term savings and efficiency gains.

Key factors to consider when choosing a screw packaging machine include:

- Packaging speed and volume capacity

- Compatibility with existing production lines

- Cost-effectiveness and return on investment

- Machine durability and maintenance requirements

Choosing wisely leads to significant productivity improvements and cost savings. A well-chosen machine not only meets current demands but also adapts to future needs, ensuring long-term satisfaction and operational success.

Maintenance and Best Practices

Regular maintenance is vital for the longevity and efficiency of screw packaging machines. Proper upkeep minimizes downtime and reduces repair costs.

Start with daily inspections, checking for wear and tear. Address minor issues promptly to prevent larger problems later on.

Follow manufacturer guidelines for cleaning and lubricating moving parts. This ensures smooth operation and extends the life of machine components.

Develop a routine maintenance schedule to keep track of tasks. Consistency in maintenance can improve machine performance and reliability.

Best practices for maintaining a screw packaging machine:

- Regularly inspect belts and rollers for alignment

- Clean sensors and remove dust from components

- Monitor for unusual noises or vibrations

Proper training for operators is essential. They should understand machine functions and routine maintenance tasks. Educated operators can quickly identify potential issues, ensuring efficient operation and minimizing disruptions to the production line.

Future Trends in Screw Packaging Automation

The future of screw packaging automation is bright, with several exciting trends. These innovations promise enhanced efficiency and higher productivity.

Firstly, the integration of smart technology is set to revolutionize the industry. Machines will feature IoT capabilities, allowing real-time monitoring and data analysis. This enables predictive maintenance and optimized performance.

Another trend is the rise of eco-friendly practices. New machines will use less energy and sustainable materials, supporting global green initiatives. This shift reflects a broader industry commitment to environmental responsibility.

Key future trends in screw packaging automation:

- Smart technology with IoT integration

- Energy-efficient designs

- Advanced data analytics for optimization

Customization will also become more prevalent. Machines are being designed to easily adapt to specific production needs, offering more flexibility. This allows businesses to maintain competitiveness and meet diverse customer demands in a constantly evolving market.

Conclusion: Why Invest in a Screw Packaging Machine?

Investing in a screw packaging machine offers numerous benefits for businesses. It enhances operational efficiency while reducing labor costs.

The machines deliver precise packaging accuracy, minimizing errors and ensuring product consistency. This leads to better customer satisfaction and improved brand reputation.

Flexible and customizable, these machines meet diverse production needs across industries. Businesses can thus adapt to market changes swiftly and effectively.

With technological advancements, screw packaging machines continue to evolve, integrating smarter features. This allows for optimized performance and sustainable operations. Therefore, investing in a screw packaging machine is a strategic move towards long-term success and profitability.