Automatic screw counting and packaging machines are widely used in the hardware fastener industry. Their core task is to accurately count screws of different specifications and pack them into bags, ensuring that the quantity in each bag is accurate to meet the needs of batch production and shipment. We will fully analyze its operating logic from the aspects of technical principles, key control points, error management and bagging mechanism.

1. Principle of accurate counting

Automatic counting is the core function of the device. Its counting methods are usually divided into the following categories:

1.1 Fiber Optic Sensing Counting

This is the most common method. An infrared photoelectric sensor is installed on the unloading channel of the equipment. When the screw passes through the channel, it will block the light. Every time the sensor senses once, the counter will be +1.

1.2 Vibrating plate + multi-channel buffer tank counting

For small particles and mixed packaging of multiple specifications, multiple vibrating plates are used for feeding, and each vibrating plate unloads materials in turn through a specific chute.

- A photoelectric sensor is installed at the exit of each channel;

- The controller determines whether to stop feeding the channel according to the set quantity.

This method is suitable for mixed counting of 1-4 specifications, such as “10 screws + 2 nuts + 1 washer”, and supports multiple combinations.

1.3 Servo driven feeding device (high-end models)

Some high-end models use servo motors to accurately control the time and quantity of material discharge, combined with visual recognition (AI cameras or laser sensors) to assist in judging the passage of particles.

2. How to ensure accurate counting and error control?

2.1 Equipment control logic: stop when quantity is reached

The required quantity can be preset in the program. For example, if it is set to 50, the system will stop the feeding system immediately after the photoelectric sensing accumulates 50 signals, and start sealing and packaging at the same time.

2.2 Real-time feedback control system

The advanced model is equipped with a PLC control system, which has:

- Self-learning function: can record the speed and shape error of different screws;

- Lack of material/stuck material alarm: prevent missed counting;

- Secondary detection: Some machines have secondary sensors for cross-verification before entering the packaging port to ensure accurate counting without omissions.

2.3 Error control range

The factory default error range is controlled within ±1 piece. Some high-precision equipment supports an error rate of <0.5% (for example, if it is set to 100 pieces, the actual range is between 99 and 101), depending on:

- Whether the screw size is uniform;

- Whether the channel is stable;

- Whether the vibration feeding is uniform;

- Whether the environmental static electricity/light interferes with the sensor.

3. How to achieve automatic bagging?

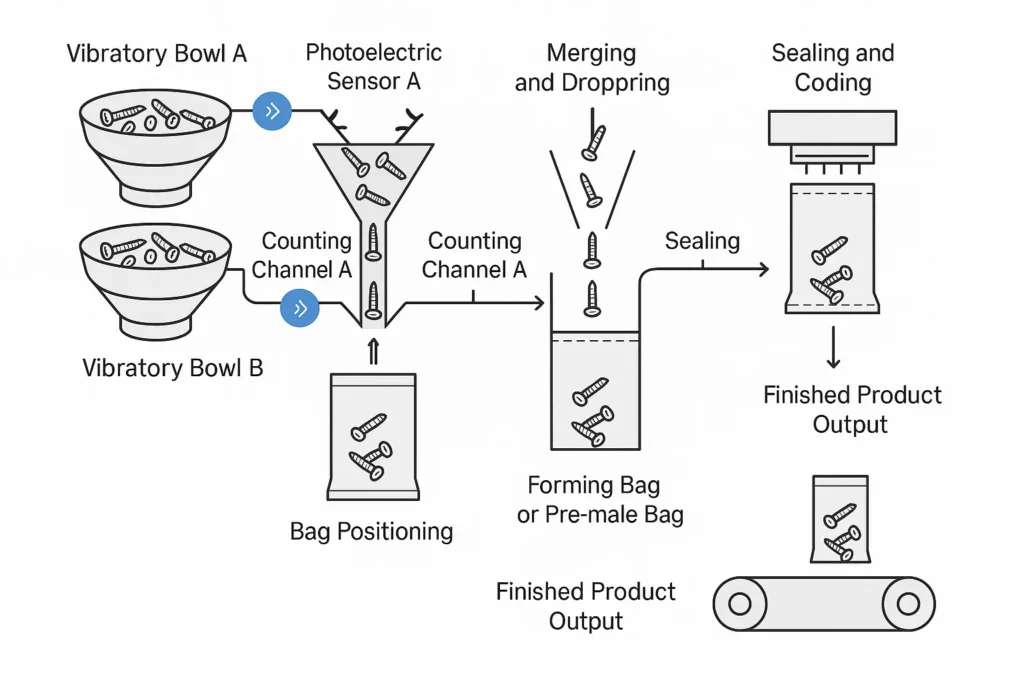

The entire automatic bagging is divided into the following links:

3.1 Material unloading and integration

- All screws fall into the merged channel through their respective channels;

- Finally, they fall together above the formed bag mouth.

3.2 Bag forming or bag pre-loading

- Roll film type: PE film automatic bag making (back seal, three-side seal, etc.);

- Pre-made bags: manual or machine automatic placement of pre-formed bags.

3.3 Material unloading triggers sealing

- After counting is completed, the system controls the material unloading;

- After unloading, the heat sealing mechanism is immediately triggered (commonly used heat sealing or pulse sealing);

- Auxiliary functions such as date coder, gas injection, exhaust, etc. can be configured.

3.4 Finished product output

- After sealing, it is output to the finished product area through the conveyor belt;

- It can be connected to a baler or a cartoner.

Flowchart (Simplified)

5. Why choose automatic counting and packaging machine?

| Project | Manual counting and packaging | Automatic counting and packaging |

|---|---|---|

| Speed | Slow | Fast (up to 60 bags/minute) |

| Accuracy | Error-prone | Very low error (within ±1 piece) |

| Cost | High (manual) | Low cost after equipment investment |

| Efficiency | Low | High (suitable for large-scale production) |

| Scalability | Poor | Upgradable to more channels and recognition functions |

6. Applicable industries

- Fastener manufacturers

- Furniture accessories packaging

- Electronic components packaging

- DIY screw package manufacturers

- Hardware packaging companies